Milk processing and dairy products production line

Out of stock

Because the soil of our motherland is considered quite favorable for cattle breeding

this industry has been developing in our country since ancient times. Animal husbandry to date

not only for the family, but also became a good source of income.

By processing dairy products for our people and for export

designed products can be produced. It should be noted that

Livestock in the territory of Uzbekistan are mainly fed with natural feed without chemical additives

it is one of the competitors in the domestic market and in the foreign market because it is fed with

a step is a column. The most important products are sterilized milk, cream, yogurt,

cottage cheese, yogurt, etc. Let’s go to the stages of production and them

let’s give detailed information about the necessary equipment.

97,100$

Out of stock

Required resources:

- Production area not less than 120 m2, washing for workers and

sanitary rooms should be within the hygiene requirements - It is up to the buyer to make a cooling chamber and a thermal chamber

- There should be a sewage system from the work area and a room ventilation system;

- Power supply rated at 380v 50hz (At least 150kw/h

durable) - 6 workers (including a laboratory assistant)

- Clean drinking water supply

The following products can be produced using this line:

1) Pasteurized milk 2) Cream 3) Cream 4) Sour cream 5) Ryazhenka 6) Yogurt 7)

Suzma 8) Cottage cheese 9) Brinza 10) Kefir 11) Yogurt 12) Buttermilk

MILK COLD STORAGE TANKER (1000L)

This equipment is the starting point for production. Repeat the daily milk

First of all, raw materials for work are collected here. Necessary for raw materials

working process is carried out in other boilers with added additives. This

cleaning the inside of our storage tank and optimizing product storage costs

placed horizontally for This cooling tanker capacity can store 1000L of milk and

1000L of milk is emptied into the remaining tanks and processed in its fresh state. Second

and in the stage, the milk in the cooling tank is pumped to the remaining tankers for processing

sent using

| Tanker for storing milk in a cold state (1000L) | |

| Manufacturer | China |

| City | Yishu |

| Operating power consumption | 5.5 kw/h |

| Speed of operation | 1000l/hour |

| Material | Stainless metal SUS304 |

| Voltage | 380V50XZ |

| Weight | 690 kg |

| number of folds | One floor |

| Cooling system | Using a chiller |

2. HOMOGENIZER FOR MILK (1000L/hour)

Homogenizer equipment plays an important role in the milk processing process. This

it is difficult to imagine milk processing without equipment. For almost all processes

this equipment is needed. Homogenizers are used in food, milk, beverage, pharmaceutical,

production, scientific research and in the fields of small chemistry and biotechnology

widely used in technology development.

Features:

1.The whole machine is covered with stainless steel coating, and the appearance is smooth and

is clean, safe and meets sanitary requirements.

2.It is helical gear low speed transmission, low noise, stable operation and reliable operation

accepts.

| Homogenizer for milk (1000L/hour) | |

| Manufacturer | China |

| City | Yishu |

| Operating power consumption | 7.5 kw/h |

| Speed of operation | 1000l/hour |

| Material | Stainless metal SUS304 |

| Voltage | 380V50XZ |

| Weight | 230 kg |

| Max pressure | 25 BARS |

3. MILK BOILER AND COOLER WITH MIXER

TANKER (1000L)

An electric heating pot for mixing, as well as materials

called mixing tank or material mixing tank, which is energy saving,

It has advantages such as anti-corrosion, strong performance and easy cleaning.

Also mainly dairy products, sugar, other elements and various drugs

used for mixing and homogenizing medicines, dairy products,

as an indispensable tool for beverage and pharmaceutical manufacturers. It is SUS304

or 316 stainless steel and it is to GMP production standard

according to An electrically heated mixing tank is the optimal conditions for enzymes

which provides decomposition and other substances due to the effect of enzymes

liquefaction tank. Jake can be used for heating or cooling,

attached with an outer heat-retaining layer. Also for pasteurization purposes

can be used.

1. Electric heating mixer

2. Covered with a layer of insulation

3. Along with the mixing system. Stirring device: With spiral agitator

equipped

4. Material: SUS 304 or SUS 316.

5. Outer skin surface: mirror polished inner surface is smooth.

6. Liquid level measurement: digital meter or measuring glass is optional.

| Tanker with milk boiling and cooling mixer (1000L) | |

| Manufacturer | China |

| City | Yishu |

| Operating power consumption | 36 kw/h |

| Speed of operation | 1000l/hour |

| Material | Stainless metal SUS304 |

| Voltage | 380V50XZ |

| Weight | 350 kg |

| Rotation speed | 30rpm |

4. TWO-STAGE FILTER FOR MILK

This filter is mainly from juice, milk, drinks and various other invisible impurities

used to get rid of. The filtering machine can be cleaned without stopping the machine

Borig will save you from unnecessary worries. It is used for a long time

if possible, it should be cleaned and washed thoroughly with water for repeated use. Material

Made of fully stainless 304 metal.

5. CENTRIFUGAL SEPARATOR EQUIPMENT (500L)

Centrifugal milk separator is used to separate cream from milk. Material

enters the drum through the feed pipe, a strong centrifugal force field

through, the material takes the neutral holes in the disk as the separating face, and the specific gravity

expels high-strength liquid. The holes in the center of the disk are large

to the central pump (top); heavy sediment accumulates in the accumulation area; characteristically low

the weighted fluid moves inward and upward across the disk, collects, and

flows into a small central pump, the light/heavy phase is large and small respectively

is discharged through a central pump.

6. MILK AT A HIGH TEMPERATURE

PASTEURIZATION EQUIPMENT (1000L/HOUR)

To increase the shelf life of dairy products, first of all, from their packaging

first sterilization is recommended. Sterilization equipment briefly heats the product to 130C

and sterilizes it by rapid cooling again.

Sterilization process: ultra high temperature instant sterilization machine general

material is stainless metal, in a heat exchanger for preheating

consisting of a centrifuge pump sterilization machine, filled with high temperature

After tanking, keep germs and enzymes at 139C for 3 seconds

was killed. Heat exchange with cold material for cooling after the heat barrel

through, the average temperature is lowered below 35 °C. after that the product

packing will be possible. Not only milk, but also juices are sterilized in this way.

| Equipment for sterilizing milk at a high temperature (1000L/hour) | |

| Manufacturer | China |

| City | Yishu |

| Operating power consumption | 36 kw/h |

| Speed of operation | 1000l/hour |

| Material | Stainless metal SUS304 |

| Voltage | 380V50XZ |

| Weight | 450 kg |

| Desktop size | 400*400 mm |

| Temperature | 115-139 C |

| Sterilization time | 4-6 seconds |

7. Laboratory equipment

High Quality Milk Testing Equipment / Milk Fat Tester

Main features:

• User-friendly: operation, maintenance, adjustment and installation

simple

• Portable and compact design

• Very little milk is required

• low power consumption

• The use of hazardous chemicals is prohibited

• The measurement accuracy value is realized through the user RS 232 interface

possible

• ESC POS printer support

• Self-calibration of two samples

Environmental conditions

Ambient air temperature – 10 ° C – 40 ° C (option 43 ° C)

Milk temperature – 1 ° C – 40 ° C

Relative humidity – 30% – 80%

Electrical parameters

AC power supply voltage – 220V / 110V

DC power supply voltage – 12V to 14.2V

Power consumption 30W maximum

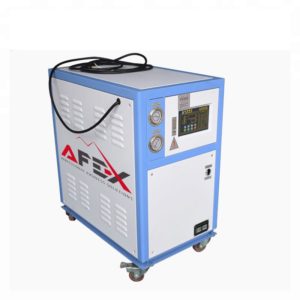

8. REFRIGERATION CHILLER (5HP)

To cool products in tankers, we need a water cooling system, that is, a chiller

will be

1. The system is protected against overloads, low and high pressure protection and electronic

time delay protection device and other abnormal condition indication

system.

2. Newly imported compressors and high efficiency shell and tube condenser,

evaporator, strong cooling ability, noiseless and energy saving, micro-

has a full computer control, easy operation system.

3. Liquid crystal display of cooling water and inlet screen (optional).

5. Comfortable and stylish appearance

| Cooling chiller (5 HP) | |

| Manufacturer | China |

| City | Yishu |

| Operating power consumption | 4 kw/h |

| Speed of operation | 300l/min |

| Material | Stainless metal SUS304 |

| Voltage | 380V50XZ |

| Weight | 350 kg |

| Desktop size | 400*400 mm |

| Freon | R22 |

9. EQUIPMENT FOR VACUUM PACKAGING OF PRODUCTS

Single-chamber vacuum packaging equipment for us cheese and other products without air

helps to pack in case. Worms, sausages, using vacuum packaging

cheese, cheese sticks and other products can also be packaged.

| Equipment for vacuum packaging of products | |

| Manufacturer | China |

| City | Yishu |

| Operating power consumption | 0,5 kw/h |

| Speed of operation | 6-18/min |

| Material | Stainless metal SUS304 |

| Voltage | 220V50XZ |

| Weight | 70 kg |

| Desktop size | 400*400 mm |

| Vacuum level | 0,4-0,6 Mpa |

10. EQUIPMENT FOR THE PRODUCTION OF PET VESSELS

PET bottles are the main packaging product for yogurt and yogurt products

remains. To produce PET bottles, you need a PET capsule, which

can be found in different regions of our country. Pet capsule is heated to the required temperature and it

formed in high pressure air. by adding one piece of customer-required mold to the equipment

is given.

| Equipment for the production of pet dishes | |

| Production | China |

| Voltage | 380V 50XZ |

| Power consumption | 14kw/h |

| Material | Carbon metal |

| Weight | 1100 kg |

| PET container size | Max 2l min 0.33l |

| Speed of operation | 800-1000 units/hour |

| The size | 1630*620*1590mm/750kg |

| Capsule heating equipment | 1780*570*1380mm/ 350 kg |

| Additional parts | Air compressor, 1 case, air filter |

11. TWO-HEAD LIQUID PRODUCTS PNEUMATIC

CASTING EQUIPMENT

This series casting machine has simple structure, high precision and easy

works, can be used in the field of food and medicine. It is of high viscosity

are the best equipment for filling materials. According to GMP, which binds them

Parts and materials are all made of 304 stainless steel. With filling volume

adjustable, filling speed can be changed as you like, high filling

precision, designed filling device with drip function. Yogurt cream, yogurt and

is the best solution for smoothies. Adjusting the equipment to the pedal and in automatic mode

can also be used.

| Two-head liquid products pneumatic burning equipment | |

| Manufacturer | China |

| City | Yiwu |

| Operating power consumption | 0,3 kw/h |

| Speed of operation | 8-14/min |

| Material | Carbon metal |

| Voltage | 220v 50hz |

| Weight | 40 kg |

| PET container filling volume | 100-1000ml |

| Air pressure | 0,4-0,6 mPa |

12. THERMO FOR FILM LABEL ON PET BOX

TUNNEL

This equipment is now somewhat popular 330ml; 500ml PET bottles

is essential for our packaged yogurt products. Also PET

we also use thermal film packaging for yogurts packaged in containers

possible

| Thermotunnel for PET container film label | |

| Manufacturer | China |

| City | Yiwu |

| Operating power consumption | 1,3 kw/h |

| Speed of operation | 0-12/min |

| Material | Carbon metal |

| Voltage | 220v 50hz |

| Weight | 40 kg |

| PET container filling volume | 250-500ml |

13. PACKAGING EQUIPMENT IN CUP-SHAPED CONTAINERS

Automatic product pouring and capping for paper and plastic cups

aluminum foil wrapping equipment. With this equipment, you are cream, gas free

buttermilk, yogurt, milk, yogurt and other products can be packed. In this package

due to the fact that the products are easy to use and the cost of the product is relatively cheap

will come.

| CUP PACKAGING EQUIPMENT | |

| Manufacturer | China |

| City | Yiwu |

| Operating power consumption | 1,6 kw/h |

| Speed of operation | 2000/h |

| Material | Stainless steel S304 |

| Voltage | 220v 50hz |

| Weight | 160kg |

| Air pressure | 0,4-0,6 mPa |

| Burn size | 10-300 ml |

14. CENTRIFUGAL PUMPS 3T

It is necessary to transfer dairy products from one equipment to another in a timely manner

comes because the lost time causes you to lose the quality of your product

possible Therefore, automatic control of the line and pumps for product transfer

necessary. Pumps are made of stainless metal, which negatively affects the quality of the product

does not

| Pump | |

| Manufacturer | China |

| City | Yiwu |

| Operating power consumption | 0,75 kw/h |

| Speed of operation | 1000/h |

| Material | Stainless steel S304 |

| Voltage | 220v 50hz |

| Weight | 15 kg |

15. STERILIZED MILK IN PLASTIC FILM

PACKAGING EQUIPMENT

Abandoning PET and Aseptic Carton Bottles Worldwide to Lower Milk Costs

in progress. Therefore, it is up to you to make your product affordable

produce your sterilized milk products packaged in PE rolls

we advise. This equipment has high performance and other if necessary

products such as buttermilk or other liquid products can also be used in packaging

will be possible.

| Liquid milk packaging equipment (200-1000ml) | |

| Manufacturer | China |

| City | Yiwu |

| Operating power consumption | 1,5 kw/h |

| Speed of operation | 1500-2000/h |

| Material | Stainless steel S304 |

| Voltage | 220v 50hz |

| Weight | 420 kg |

| Coding material | OPP, PE, PE+AL |

Based on 0 reviews

Show reviews in all languages (2)

There are no reviews yet.