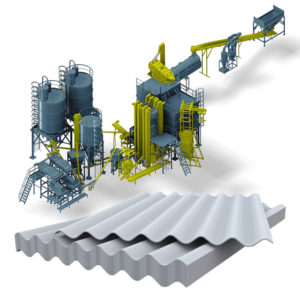

Cement production plant (150 tons per day)

Out of stock

Hello, dear customers of AFEX-GROUP. We will continue to provide you with profitable and profitable production equipment and lines.

In this post, we aim to highlight one of the most profitable types of business. You will need a lot of money to start this manufacturing business. It should be noted that you can earn a lot of money here. This is a manufacturing business-a small cement plant.

At this point, it is appropriate to emphasize one piece of information. According to statistics, at the moment, about 8 million tons of cement are produced in Uzbekistan per year. According to the information of the state holding “Uzsanoatqurilishmaterialari” by 2026, the total cement production rate in the republic has been set to 20 million tons per year. This plan will be implemented by building new private cement plants in the republic. That is, the establishment of this production line is supported by the state. Now let’s clarify some information about the mini factory.

1,700,000$

Out of stock

General information

- Type of cement production: Dry

- Production brands: PC/M 400/500/600

- Production volume: 150 tons/day

- Raw materials: limestone, clay, iron ore, gypsum, quartz sand, natural gas and auxiliary materials

- Number of workers: 50 for one shift

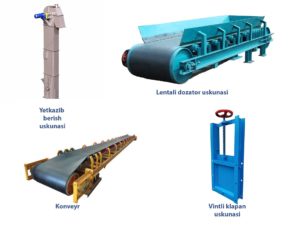

A set of equipment

- Grinding raw materials

- Storage and delivery of raw materials

- Grinding raw materials (powder)

- Heating and cooling of clinker

- Dosing cement

- Grinding and packing of cement

- Laboratory

- Low voltage electrical cabinet

So, we got acquainted with the list of necessary equipment and general information. Now it’s time to consider the production process step by step.

Grinding raw materials

We know that the main raw material for cement is limestone. Of course, we start the production process with the preparation of raw materials, that is, we grind them. For this we need the following set of equipment

| Grinding | |||

| Name | Efficiency | Amount | Power |

| Vibration equipment | 60-80 tons/hour | 2 | 2,2 kwt |

| Limestone crushing equipment | 40-110 tons/hour | 1 | 55 kwt |

| Clay crushing equipment | 18-40 tons/hour | 1 | 55kwt |

| Conveyor | 80-100 tons | 3 | 15 kwt |

Storage and delivery of raw materials

So, we chopped the raw materials to the required size. The next task is to store them in a certain place and deliver them to the next equipment.

| Delivery equipment | |||

| Name | Efficiency | Amount | Power |

| Limestone delivery equipment | 50 tons/hour | 1 | 37kw |

| Limestone screw valve | 10-30 tons/hour | 1 | |

| Limestone tape dispenser | 2-10 tons/hour | 1 | 1,1kw |

| Clay delivery equipment | 25-35 tons/hour | 1 | 15kw |

| Clay screw valve | 10-30 tons/hour | 1 | |

| Clay tape dispenser | 2-10 tons/hour | 1 | 1,1kw |

| Iron powder screw valve | 10-30 tons/hour | 1 | |

| Iron powder tape dispenser | 2-10 tons/hour | 1 | 1,1kw |

| Belt conveyor | 30-50 tons/hour | 1 | 5,5kw |

One information should be mentioned here. The above equipment only supplies raw materials. It is the responsibility of the buyer to create a warehouse for raw materials.

Grinding raw materials

At the very first stage, raw materials were crushed from large pieces to small pieces. In this grinding, those parts are reduced to powder.

You can see the equipment in the following photos:

| Delivery equipment | |||

| Name | Efficiency | Amount | Power |

| Grinding equipment | 16tons/hour | 1 | 245 kw |

| Filter | 11160m3/h | 1 | 30kw |

| Conveyor corridor | 30-60tons/hour | 1 | 3kw |

| Supplier equipment | 50 tons/hour | 1 | 37kw |

| Mixing equipment | 1 | 18,5kw | |

| Screw valve equipment | 10-30tons/hour | 1 | |

| Libra | 0-30 tons/hour | 1 | 3 kw |

| Spiral conveyor | 20-30 tons/hour | 1 | 7,5 kw |

Heating and cooling

One of the main processes of cement production is crushing, heating and cooling of clinker. The following set of equipment is needed for this.

| Heating and cooling equipment | ||||||

| Name |

|

|

|

|||

| Supplier equipment | 1 | 3 kw | ||||

| Rotary oven | 7-10 tons/hour | 1 | 62,5 kw | |||

| Coolant filter | 60 100 m3/h | 1 | ||||

| Cooling fan | 1 | 110kw | ||||

| Gas burner | 1.75×107 | 1 | 39,2kw | |||

| Drum cooler | 12-16 tons/hour | 1 | 55kw | |||

| Chain conveyor | 15-25 tons/hour | 1 | 7,5kw | |||

| Clinker crusher | 10-15tons/hour | 1 | 15kw | |||

Dosage

This process is mainly carried out with gypsum, clinker and additives. The above are added to the semi-finished cement.

| Dosage | |||

| Name | Efficiency | Amount | Power |

| Clinker silage | 1 | ||

| Lifting equipment | 25-35tons/hour | 2 | 15kw |

| Screw valve equipment | 10-30 tons/hour | 3 | |

| Tape dispenser equipment | 2-10tons/hour | 3 | 1,1kw |

| Gypsum crusher | 5-20 tons/hour | 1 | 18,5kw |

| Conveyor | 30-50tons/hour | 1 | 5,5kw |

Grinding and packing of cement

The last process. We pack cement with the help of equipment.

| Grinding and packaging | |||

| Name | Efficiency | Amount | Power |

| Clinker crushing equipment | 16 tons/hour | 1 | 245kw |

| Filter | 11160m3/h | 1 | 30kw |

| Lifting equipment | 25-35 tons/hour | 1 | 30 kw |

| Classifier | 15-30 tons/hour | 1 | 60kw |

| Chain conveyor for returning large pieces to grinding | 15-30 tons/hour | 1 | 7,5kw |

| Unloader | 80-120tons/hour | 1 | 2,2kw |

With that, all the processes have come to an end. In the video below, you can view the cement production line step by step.

| Prices | |

| Grinding raw materials |

$ 1 700 000 |

| Storage and delivery of raw materials | |

| Grinding raw materials (powder) | |

| Heating and cooling of clinker | |

| Dosing cement | |

| Grinding and packing of cement | |

| Laboratory | |

| Low voltage electrical cabinet |

Based on 0 reviews

Show reviews in all languages (6)

There are no reviews yet.