Production line of PVC profiles for Rom

Out of stock

As the construction market expands, the reformation of building materials is also developing. It is no secret that aluminum frames have gradually replaced traditional wooden frames. But aluminum frames have a big minus side, even if it passes 70% of cold and hot air from the street. This requires a lot of electricity to keep the room temperature at the same level in winter and summer. Considering this, the current market demand is for plastic frames made of PVC profiles.

187,900$

Out of stock

Today’s business project is about PVC profiles, which are the main product type for metal-plastic frames.

General information about the project:

- Production capacity: 300-350kg/hour

- Required working space: 30m x 10m building

- Required manpower: 5 people (for 1 shift)

- Energy consumption: 80KW/hour

- Voltage: 380V 50Hz

Brief information about the history of PVC profiles:

Plastic frames are so common that today it is an indispensable attribute of any modern design. But 50 years ago, no one knew what it was.

The history of the appearance of polyvinyl chloride (PVC) began in 1835. It was in this year that the American chemist Regnald managed to invent polyvinyl chloride, which later became the material from which plastic windows began to be produced.

The first industrial production of plastic windows took place in the USA in the 50s. Later, Europe saw a great prospect and began to develop and apply these technologies. And soon, in 1952, German developers were the first to create and patent the construction of PVC windows.

PVC frames began to appear in our country in the mid-90s, at first such profiles were imported from abroad, and due to the high price of frames, not everyone could afford to install such frames at that time. By the 2000s, the production of PVC frames in our country and market competition made PVC frames an acceptable building material for everyone.

It should be noted here that PVC frames differ from traditional wooden frames in terms of their resistance to external impacts and weather changes, fire resistance, high energy efficiency, beautiful design and noise reduction. It excels with the qualities of impermeability.

In addition, the number of chambers of PVC profiles is important in maintaining a moderate room temperature.

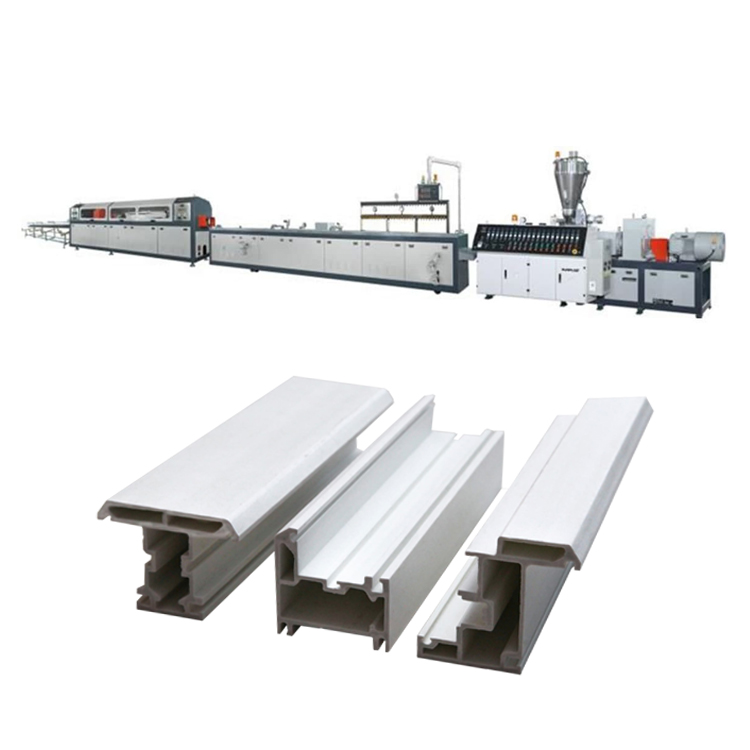

Now let’s turn to the production process. The production line of PVC profiles for Rom consists of 3 major parts. These are:

1. PVC profile extrusion line

2. Part of preparing the mixture

3. Lamination line

1.PVC profile extrusion line

General view of the line

| PVC profile extruder line | |

| Produced | China |

| Production environment | Dry and clean building |

| Total length | 23 m |

| Power consumption | 80 sq/h |

| Voltage | 380V/50Hz |

| Sort by | 300-350kg/hour |

| Product width | Max 250mm |

| Equipment width | 1.45 m |

| Equipment height | 1050±50mm |

1.1 Extrusion part

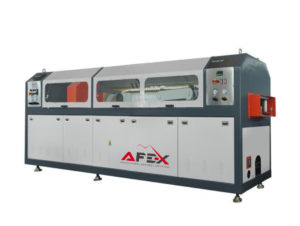

Twin screw extruder equipment

| Twin screw extruder equipment | |

| Produced | China |

| Model | AFX65-132 |

| Heating parts | 4 |

| Power consumption | 37 sq/h |

| Voltage | 380V50Hz |

| Nitrogen layer | 0.55-0.7mm |

| Oil heating temperature | 0-180C |

| Metal type | S304.20CrMoTi |

The PVC profile production line consists of an extruder, a film, a calibration table, a weighing device, a profile saw and mechanisms for marking, laying and applying a protective film to the finished product (profile).

Production is carried out by extrusion. Extrusion is a continuous process of extruding a preheated mass of polymer through shaped holes in a mold. The extruder ensures the melting of the mixture and the continuous supply of the solution under a certain pressure.

1.2 Marking Section.

| Single screw coextruder | |

| Produced | China |

| Model | AFX-30/25 |

| Heating parts | 4 |

| Power consumption | 5.5 kw/h |

| Voltage | 380V50Hz |

| Nitrogen layer | 0.4-0.5mm |

| Oil heating temperature | 0-180C |

| Production volume | 8-10 kg/h |

1.3 Calibration part

| Calibration equipment | |

| Produced | China |

| Model | AFX-300 |

| Heating parts | 4 |

| Power consumption | 11.7 kw/soat |

| Voltage | 380V50Hz |

| Water pump | 2 (2.2 kw and 4 kw) |

| Equipment length | 7200mm |

| Table management | Automatic |

The calibrator gives the desired shape to the mass of the solution. The puller pulls the profile out of the calibrator at a stable speed, providing optimum force.

1.4 Cutting part

| Cutting and transfer equipment | |

| Produced | China |

| Model | AFX-300 T |

| Length of rubber pads | 300 mm |

| Power consumption | 3,7 kw/h |

| Voltage | 380V50Hz |

| Engine power | 1,5 kw |

| Production capacity | 5m/min |

| Compressive strength | Pneumatic |

The saw cuts the profile to the required length.

1.5 Assembly

| Special profile assembly equipment | |

| Produced | China |

| Model | AFX-6000 |

| Equipment length | 6000 |

| Power consumption | 380V50Hz |

| Voltage | Collection of profiles |

| Hardware function | From 1-40 |

| Capacity of profiles | Semi Automatic |

| Work style | Pneumatic |

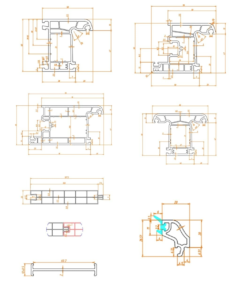

2. Special molds

“AFEX-GROUP” offers you 8 types of special molds. With the help of these molds, you can produce PVC profiles of any shape for frames.

3. Mixing part

Mixer part

| Hot mixer 500L | |

| Produced by | China |

| Model | AFX-SRL300 |

| The floor of the shoulder blades | 3 floors |

| Power consumption | 75 kw/h |

| Voltage | 380V50Hz |

| Max. input | <150kg/lot |

| Working capacity | 375L |

| Total capacity | 500L |

| Bearing rotation speed | 430-860 units/min |

4. Lamination line

| Lamination line | |

| Produced | China |

| Voltage | 380V50hz |

| Power consumption | 12kw/h |

| Max. working width | 300mm |

| Wheel width | 2-80 mm |

| Main motor | 1.5 sq |

| Gluing motor | 0.37 sq |

| Heating tunnel capacity | 4 sq |

| Total weight | 2500 kg |

Laminated look

Finished products:

Ishlab chiqarish jarayonidan video lavha:

| General prices | ||

| PVC profile production line | 1.Extrusion part

2.Marking part 3. Calibration part 4. Cutting part 5. Assembly and cutting part |

64 000$ |

|

Molds |

78×60

58x60mm 80×60 115×60 107.5x20mm 60.2x12mm 20×26.51mm Two cameras |

9 700$

9 300$ 10 600$ 10 600$ 8 000$ 5 600$ 6 700$ 7 600$ |

| Mixture preparation line | Hot mixer part | 11 500$ |

There are no reviews yet.