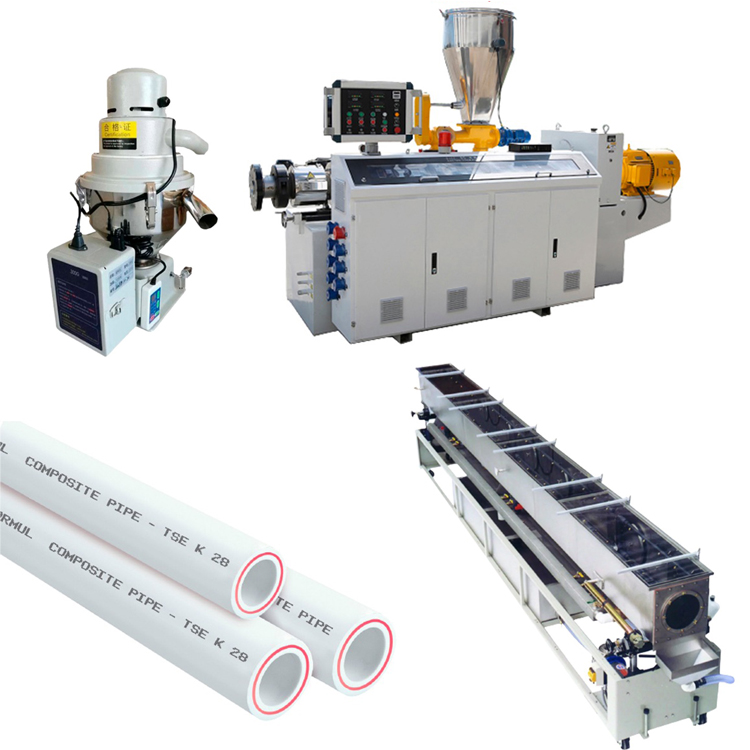

PPR pipe production line

Out of stock

The main dream and goal of every person’s life is to build his own house. A lot of construction equipment and raw materials are needed to build a luxurious and comfortable, modern and durable house. Nowadays, the construction of every house cannot be imagined without plastic pipes (PPR pipes). Our next production line will be about PPR pipes. First, let’s talk about the achievements of this type of pipes.

89,000$

Out of stock

Useful features

- Low thermal conductivity. The thermal conductivity of the PPR material is very low, that is, it does not easily transfer the hot or cold temperature of the external environment to the liquid in the pipe and vice versa. This factor reduces heat loss when hot or cold fluid is transferred, resulting in energy savings and reduced insulation costs for PPR pipes.

- Long service life and durability. PPR pipes can serve you for more than 50 years despite different working environments and temperatures. PPR pipes show high efficiency and durability both in hot and cold water. At the same time, PPR pipes, unlike other common types of plastic pipes, do not break or crack during installation in cold weather.

- Effective internal surface. Compared with traditional pipe types, the inner surface of PPR pipe is very smooth and the friction coefficient is very low. This leads to a reduction in pressure losses during fluid transportation and distribution and helps to increase the energy efficiency of PPR pipe systems. In addition, unlike metal pipes, PPR does not break or rub, which makes them safer to use.

- Chemical and mechanical resistance. Compared to traditional plastic pipes, PPR pipes are resistant to hard and abrasive substances. This is especially useful when used for industrial purposes or well water with abrasive particles in the fluids being transferred.

- Environmental and economic efficiency. Due to the low weight of PPR pipes, their transportation, processing and installation do not require a large amount of energy consumption or manual labor. At the same time, it is very easy to cut, join and work with them. In addition, connecting PPR pipes to each other is done only by heat and does not require additional chemicals and materials. All these factors lead to lower environmental impact and lower operating costs.

- Aspects of use. The durability, economic and environmental advantages of PPR have led to its use for various purposes in recent years.

Now let’s get acquainted with the general information about our pipe production line.

General information

- Raw materials: PPR chemical, plain and colored pigments

- Production capacity: 50-150 kg/hour (depending on pipe sizes and working conditions)

- Size of plastic pipes: 20-63mm

- Plastic pipe type: 3 layers

- Line dimensions: 35m*5m*3m (length*width*height)

- Temperature: ≤40°C

- Voltage: 380V, 50Hz

- Power: 76kw

- In the room, it should be easy to supply water to the equipment, electricity should be stable.

- Number of workers: 1 or 2

- Water cooling: 20°C, ≥0.3Mpa, ~2~3 m3/h

- Compressed air: 0.3m3/min, 0.3Mpa-0.8Mpa

Now we can move on to the production processes and the equipment needed for the implementation of these processes.

Supplier equipment

So, first of all, we need a device that delivers raw materials to the equipment. This is exactly what the above equipment does. It automatically pulls out the contents of the container and delivers them to the drying hopper. Since the number of extruders in our production line is 2, the number of supplying equipment will also be 2.

| Supplier equipment | |

| Capacity | 300 kg |

| Type of operation | Vacuum |

| Engine power | 1.5KW |

| Max vacuum pressure | 12000Pa |

| Delivery hose size | F32mm |

| Management | Delivery time can be customized |

PPR pipe production line

Melting hopper

It was the turn of the smelting hopper. The raw materials were placed in this equipment using the delivery equipment. The function of this equipment is to dry and melt the raw materials to the extruder. 2 melting hoppers are used for 2 extruders. The capacity of the first bunker is 100 kg, and the second one is 50 kg.

| Melting hopper | |

| Load capacity | 50kg |

| Max operating temperature | 130C |

| Accuracy | 5C |

| Heating capacity | 5,4 kw |

| Engine power | 0,25kw |

| Material | Stainless metal |

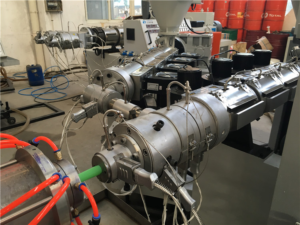

Extruders

| Extruder TK 65/33 | |

| Screw diameter | F465mm |

| Screw material | 38CrMoAIA |

| Number of heating zones | 5 |

| Electric heater material | Cast aluminum+stainless metal |

| Heating capacity | 2.8kw*5 |

| Cooling capacity | 0.17kw*5 |

| Motor type and power | AC37KW |

| Brand | Siemens, ABB, Delixi, Schneider, Omron |

| Extruder | TK 45/30 |

| Screw diameter | F45mm |

| Screw material | 38CrMoAIA |

| Number of heating zones | 3 |

| Electric heater material | Cast aluminum+stainless metal |

| Heating capacity | 2.3kw*3 |

| Cooling capacity | 0.17kw*3 |

| Motor type and power | AC18.5KW |

| Brand | Siemens, ABB, Delixi, Schneider, Omron |

Molds

Don’t forget the molds here. Molds of different sizes are placed inside the extruders. In this case, the mold diameters are made according to the customer’s request. Sizes of molds: 20, 25, 32, 40, 50, 63 mm. #40 chrome material was used for molds.

Color line extruder

We must not forget to design our PPR pipes. We will need the next equipment to make them beautiful. This equipment casts a colored line on our pipes.

| Extruder Tk 25/25 | |

| Screw diameter | 25 mm |

| Screw material | 38CrMoAIA |

| Number of heating zones | 2 |

| Electric heater material | Cast aluminum+stainless metal |

| Heating capacity | 0,85kw*2 |

| Cooling capacity | 0,06kw*2 |

| Motor type and power | AC 1,1 KW |

| Brand | Siemens |

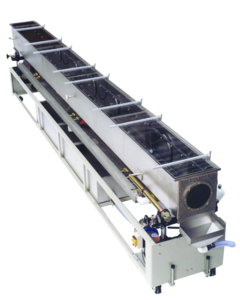

Vacuum gauge equipment

The function of vacuum calibration equipment is to maintain the shape of plastic pipes. The tubes coming out of the extruder are hot. It is very easy for them to change shape when it is hot. This equipment is a solution to this problem with the help of vacuuming.

| Vacuum calibration equipment | |

| Length | 6m |

| Vacuum pump power | 4kw*2 |

| Vacuum pressure | 0,03-0,06 mPa |

| Water pump capacity | 4kw*2 |

| Material | Stainless steel, silicone |

Water cooler

In order to further improve the quality and durability of our products, we also cool them with water. For cooling, we need the above 4 meter stainless steel equipment. It is advisable to put room temperature water in them.

Laser marking equipment

Writing various information on the top of the pipes has recently become a common practice. For this, the above small equipment will be enough for us.

| Laser marking equipment | |

| Accuracy of operation | 0,01mm |

| Weight | 70kg |

| Marking field | 110mm*110mm |

| Management | PLC control |

| Power | 30W |

Corrective equipment

This equipment is used to shape pipes. Pipes pass between two belts and are pressurized. Under this pressure, the pipes are shaped and transferred to the next stage.

| Corrective equipment | |

| Working length | 1800mm |

| Pressure | 20000N |

| Speed | 1-10m/min |

| Engine power | 2,2kw |

| Motor brand | ABB inverter |

Cutting equipment

This equipment cuts plastic pipes according to the length required by the customer. A distinctive feature of the equipment is that it does not emit any dust or debris when cutting a plastic pipe. When plastic pipes are cut in conventional equipment, scraps of those pipes are formed and as a result the quality of the product is damaged. And there are no extra parts coming out of this equipment. The tool blade rotates around the pipe and cuts the pipe.

| Cutting equipment | 1,1kw |

| Engine power | 70mm |

| The blade is diametric | 1-10m/min |

| Management | PLC control system |

| Parts brand | Schneider and Delihy |

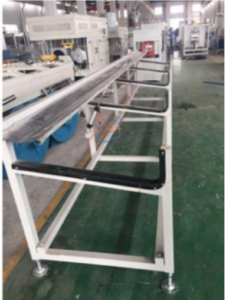

Cutting equipment

The PPR pipes coming out of the cutting equipment go to the assembly equipment. This equipment is 6 meters long and made of stainless steel.

This is the end of the information we want to present to you. Now, let’s get acquainted with the equipment prices.

There are no reviews yet.