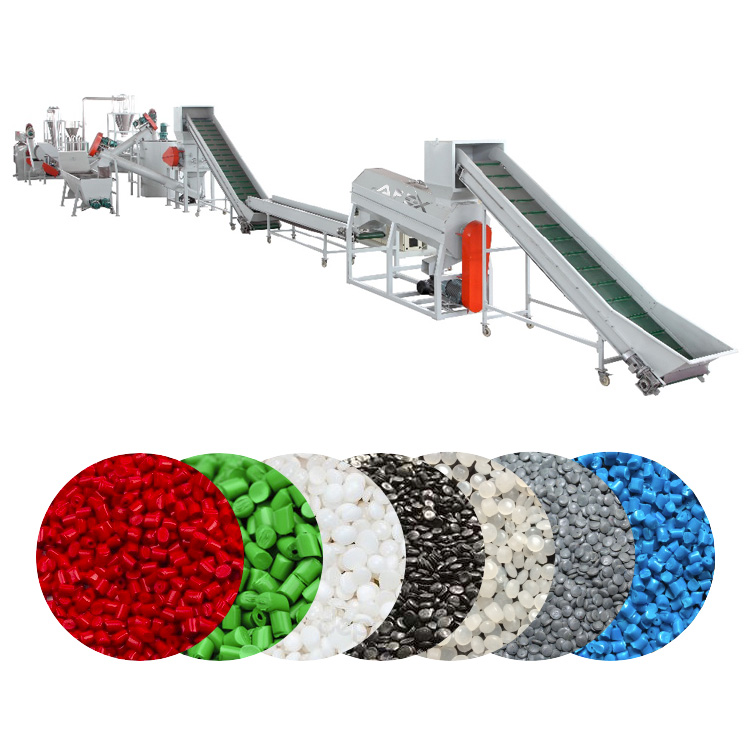

PE / PP waste processing line

Out of stock

As the production sector is developing in the modern world, attention is being increasingly paid to the waste processing sector. Currently, in all developed countries, the processing industry occupies a significant place in the ecological economy of the country, and the international community is also demanding it.

At the same time, the amount of investments in this field has been increasing in our country in recent years. For this reason, AFEX-GROUP company members offer a variety of recycling equipment in order to help entrepreneurs contribute to the economy and ecology of our country. It is the turn of our equipment for processing polyethylene and polypropylene cellophane products.

155,800$

Out of stock

General information

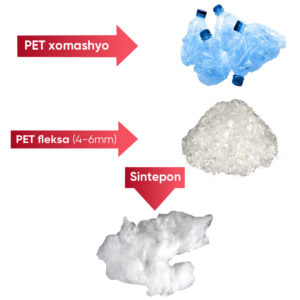

Raw materials: PE and PP cellophane, package and plastic products

Production volume: 400-500 kg/hour

Total capacity: 210 kw/h

Water consumption: 5 tons/hour

Number of workers: 4-5

Total required area: 150 square meters

Final product state: granule

Equipment list

Now let’s get acquainted with the list of all the equipment in the processing line. The line generally consists of two parts: grinding-washing, granulation.

Grinding-washing

- Conveyor

- Grinding equipment

- Washing equipment

- Washing pools

- Special sediment conveyor

- Delivery equipment

- Drying equipment

- Control point

Grinding into granules

9. Conveyor

10. Extruder

11. Drying equipment

12. Vibrator

13. Control point

Recycling process

Washing-grinding

Now let’s take a closer look at all the stages.

The first stage

So, we put all waste and raw materials on a special conveyor. This conveyor delivers to the next crushing equipment in its direction. The equipment has a 1.5 kW motor, and the working length is 6 m in total.

The second stage

One of the main equipment in this section is the crusher equipment. He grinds all the raw materials to the required size.

- New blade design, increase production.

- High speed dynamic balance. The noise is less than the old generation equipment and the grinder is equipped with shock absorption system to ensure continuous operation.

Crusher equipment Engine power 6kw Number of stationary blades 4 Number of rotating blades 6 Blade material SKD11 Spindle speed 650rmp General dimensions 2300*1250*1400mm Equipment weight 1,75T

The third stage

In the next equipment, crushed packages, cellophane are cleaned of solids. The task of the equipment is to catch them and deliver them to the next washing equipment.

| Crusher equipment | |

| Engine power | 11kw |

| Rotation speed | 500r/min |

| Working dimensions | 380*3500mm |

| Material | Carbon metal |

| Weight | 1,1T |

The fourth stage

In this washing machine, we clean only water-soluble products from waste. Solids such as sand, stone and PVC settle to the bottom of the washing tank. Sediments are removed through a special auger conveyor.

The fifth stage

At the very last stage of the recycling process, the bags are washed again.

| Washing machine | |

| Engine power | 1,5kw |

| Dimensions | 4000*1000*400mm |

| Weight | 380kg |

The sixth stage

At the very last stage of the first washing-grinding part, the ground products are dried. All processes are regulated through the control point.

| Drying equipment | |

| Engine power | 30kw |

| Spindle rotation speed | 1400rmp |

| General dimensions | 2,25*1,5*1,6 m |

| Capacity | 500kg |

| Material | Carbon (inside SS304) |

| Weight | 1000kg |

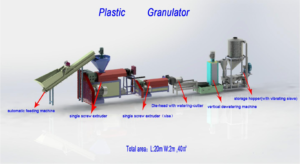

Granulation

The first stage

At this stage, the dried-crushed waste is once again crushed into granules. For this we need all the equipment in the picture above. 2 extruders are included in the equipment set.

| Main extruder | |

| Screw diameter | 250 mm |

| Screw length | 3,6 metr |

| Screw material | 40Cr |

| Engine power | 90kw(inverter) |

| Electromagnetic heating power | 240kw(80kw*3) |

| Additional extruder | |

| Screw diameter | 200 mm |

| Screw length | 1,6 metr |

| Screw material | 40Cr |

| Engine power | 45kw |

| Heating capacity | 20kw |

The second stage

Pellets are cut using this equipment. It is also washed and cooled with water during the cutting process.

| Cutting equipment | |

| Engine power | 1,5kw |

| Working power | 10kw |

| Cooling tank dimensions | 2500*350mm |

The third stage

At the last stage, we dry our washed granules. After drying, they are ready for sale.

| Drying equipment | |

| Engine power | 5,5kw |

| Spindle rotation speed | 1450 r/min |

| Equipment dimensions | 1200*1150*1800mm |

| Material | Stainless metal |

Finally, a vibrating silo is needed to clean the finished products.

| Vibrating silo | |

| Engine power | 3kw |

| Material | Stainless metal |

| Size | 3 metr/kub |

It is managed through a control point to control the equipment.

A video of the working process

There are no reviews yet.