Ice cream production line

Out of stock

Each season sells a lot of different products. Due to the onset of hot days in our country, the ice cream business has started to revive. Therefore, in this post, AFEX-GROUP recommends its equipment to you, dear customers, to start this type of small business. With this equipment, you can make different types of ice cream, and most importantly, there is a wide variety of molds.

14,900$

Out of stock

Production line composition

The production line consists of the following equipment:

- Refrigerator

- Packaging equipment

- Heating equipment

- Mixer

- Pasteurization equipment (with cooling function)

General information

- Production capacity: 120-2280 pieces/hour (depending on the equipment and mold)

- Energy source: Electricity

- Voltage: 220V 50Hz

- Power: 20KW

- Number of workers: 2

- Required area: 40 square meters

- Ingredients: ice cream recipe ingredients, glycoside/glycol/salt/calcium chloride, water, packets, wooden sticks.

Now let’s talk about the principles and processes of the equipment.

Refrigerator

So, the first piece of equipment we need is a mold ice cream freezer. The function of the equipment is to freeze ice cream placed in molds. There are different types of equipment in different models and sizes.

| Model | The number of colips | Work efficiency (per hour) |

| MAF-01 | 1 | 120-160 pieces |

| MAF-02 | 2 | 240-320 pieces |

| MAF-04 | 4 | 480-640 pieces |

| MAF-06 | 6 | 720-960 pieces |

| MAF-08 | 8 | 960-1280 pieces |

| MAF-10 | 10 | 1200-1600 pieces |

| MAF-12 | 12 | 1440-1920 pieces |

| MAF-18 | 18 | 2160-2880 pieces |

We will familiarize you closely with the equipment under the MAF-08 model.

You can familiarize yourself with the technical parameters of the equipment in the table below.

| Refrigerator | |

| Model | MAF-08 |

| The number of colips | 8 TA |

| Sigimi | 690-1280 TA/HOUR |

| Voltage | 220V/380V, 50/60 HZ |

| Power | 7800w |

| Material | SS201-SS304 |

| Equipment dimensions | 270*100*100 CM |

| Weight | 380KG |

At this point, we should emphasize one piece of information. There are various forms of molds intended for the equipment, among which we can make and bring special molds according to the customer’s request. 8 molds are included in the equipment price. The price of one additional mold is $400, and the price of one custom-made mold is $550.

We use the equipment in the following order:

- We put the antifreeze in the tank.

- We start the equipment and set the temperature on the control panel to -20 degrees. It takes 4 hours to reach this temperature the first time.

- When the temperature reaches -20 degrees, we place the molds with the mixture in the equipment.

- After 15-20 minutes, we separate the molds and soak them in warm water. The purpose of this is to ensure that our ice creams are easily separated from the molds.

As mentioned above, a coolant is needed to use the equipment. We can use glycoside, calcium chloride or glycol/sea salt as a cooling agent. Sea salt is usually used.

| Model | GLYCOL | MARINE TYPE/ CALCIUM CHLORIDE |

| MAF-01 | 50 L | 36KG |

| MAF-02 | 110L | 79KG |

| MAF-04 | 171L | 123KG |

| MAF-06 | 241L | 173KG |

| MAF-08 | 322L | 230KG |

| MAF-10 | 399L | 287KG |

| MAF-12 | 455L | 327KG |

| MAF-18 | 623L | 520KG |

Heating equipment

We put the molds from the freezer into the equipment. Water is boiling inside the equipment. By placing the molds in hot water, it becomes easier to separate our ice creams.

| IGNITION EQUIPMENT | |

| Sigimi | 1 case |

| Voltage | 220V 50Hz |

| Power | 1500w |

| General dimensions | 55*52*460 cm |

| Weight | 20 kg |

Mixer

All raw materials are mixed with this equipment. Well-mixed raw materials serve as the basis for the production of quality ice creams.

| Mixer | |

| Sigimi | 40l |

| Voltage | 220V 50Hz |

| Power | 370w |

| General dimensions | 75*65*137cm |

Pasteurization equipment

The process of pasteurization can be expressed in one word – sterilization. Pasteurization equipment cleans milk from various bacteria, germs and harmful substances. The heating temperature rises to 85-100 degrees. The equipment is made of stainless steel SUS304 material.

This milk pasteurizer has a stirrer so the milk can be heated or cooled evenly. Heating the milk at a high temperature and cooling it for a short time removes harmful substances from the milk. There is a thermometer that shows the temperature during pasteurization. In the interior of the equipment, the homogenizing blades are also placed. In this way, we can increase the quality and unity of our products. Milk products that have passed the homogenization stage have a good taste and can be stored for a long time.

| Homogenization and pasteurization equipment | |

| Sigimi | 100l |

| Voltage | 220V 50Hz |

| Power | 9000w (heating), 950w (cooling) |

| Sterilization temperature | 0-99 С |

| Duration of sterilization | 30-60 minutes |

| Cooling temperature | 3-9 С |

| Weight | 250 kg |

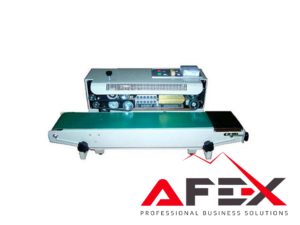

Packaging equipment

At the end of the production process, we need to pack our finished ice cream.

| Coding equipment | |

| Speed of operation | 0-20 units/minute |

| Voltage | 220V50XZ |

| Power | 50 watts |

| Packet width | 6-12 mm |

| Pack thickness | 0.02-0.8mm |

| Operating temperature range | 0-300S |

| Load weight | 5 kg |

| General dimensions | 840*380*320 mm |

With this, our production process has come to an end.

| Price | |

| Refrigerator (MAF-08) | |

| Mixer | |

| Exciting equipment | $ 14900 |

| Pasteurization equipment | |

| Coding equipment |

There are no reviews yet.