Abrasive disc production line for metal cutting

Out of stock

Having studied the domestic market of our country for the clients of “AFEX GROUP”, we will continue to manufacture imported products in our country and offer modern technologies to our entrepreneurs!

167,900$

Out of stock

Day by day development is humanity’s continuing to create conveniences for itself. Since the 80s of the last century, when cutting iron or hard objects was a problem, abrasive discs became the solution to this problem. Abrasive cutting discs are mainly produced according to the following body types.

- Wood

- Metal

- Bricks

- Concrete

- Marble-Granite

We will try to explain in detail the necessary raw materials and technologies for the production of metal cutting abrasive discs, which are mainly useful for the customers of AFEX GROUP. Metal cutting abrasive discs are mainly imported from Russia and China. You can reduce the amount of imports by producing this product.

The fact that the production process of this product is not complicated, it is suitable for both new businessmen and experienced entrepreneurs.

REQUIRED PRODUCT INFORMATION.

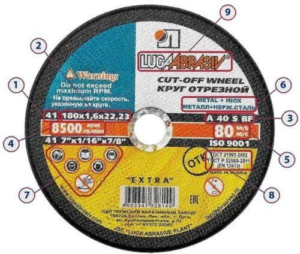

The photo above shows a disc marked according to state standards for cutting metal. The areas of the disk are marked with numbers, these numbers mean:

- Constructive type (ISO 41, flat).

- Geometric characteristics – diameter, thickness, hole.

- Physical characteristics: abrasive type (A – electrocordum); grain size; degree of hardness (Latin T – very hard); type of connection (BF – reinforced bakelite).

- Maximum rotation speed.

- Maximum peripheral speed allowed.

- For which material it is intended.

- Security icons.

- Reference to regulatory documents.

- Manufacturer’s logo.

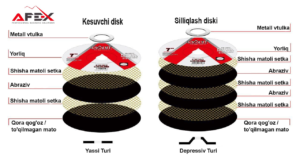

The production of the flat type of cutting discs on this line is calculated in the total amount. If you want to produce the depressed type as well, you are required to purchase these product molds.

PRODUCTION PARAMETERS

It uses cutting discs of the necessary sizes for various Bulgarians. We have also selected technologies that produce metal cutting discs that are widely used.

- Outer diameter: 100,115,125,150,180,230 mm;

- Diameter of the central ring: 22.32 mm;

- Thickness: 1.0, 1.2, 1.6, 1.8, 2.0, 2.5, 3.2 mm

RAW MATERIALS REQUIRED

- Abrasive particles.

- Resin powder.

- Cryolite.

- Gypsum powder.

- Black carbon.

- Fiberglass mesh.

- Special black paper (for the bottom part).

- Colored aluminum oxide (on the surface).

- Metal folk.

SALE

In our country, you can find abrasive discs that are mainly imported. The purchase of the product depends on the level of quality. The simplicity of product production increases the possibility of substituting imported products. The fact that the product becomes useless during the cutting process ensures the sustainability of sales.

AREA REQUIRED

The area required for this line should not be less than 150m/sq. If there is an opportunity for light trucks to enter or take out raw materials and finished products, it will increase the productivity.

REQUIRED SUPPLY

Elements of the infrastructure of the industrial facility must be provided with electricity, water supply.

• Line power – 125 KW/380V, 50HZ.

•Required transformer-above 160KW/380V, 50HZ.

• For 1 ton of product – 300 KW energy consumption.

• The number of workers requires 8-10 people.

PRODUCTION MECHANISM

EQUIPMENT AND DEVICES IN THE LINE

•Equipment for cutting glass fiber nets.

•Metal folk making equipment.

•Vibrating sieve.

•Two bowl hydraulic mixer.

•Abrasive disc preparation equipment (100,115,125 mm).

•Abrasive disc preparation equipment (150,180,230 mm).

•Special electric oven.

•Balance checking equipment.

• Testing equipment.

•Air compressor.

We learned about the necessary information about the product and the production mechanism in detail. Now let’s get acquainted with the equipment of the line.

FIBERGLASS CUTTING EQUIPMENT

Fiberglass mesh cutting equipment – with this equipment, you can cut it to the desired size mainly by hand. These meshes serve to strengthen the shape of the abrasive disc. Products cut to size are sent to automatic abrasive disc making equipment.

| Cutting equipment (PRESS) | |

| Cutting strength | 20T |

| Desktop size | 500*1000 mm |

| Kroonstein size | 350*550mm |

| Power | 1,5kw |

| Voltage | 380v, 3faza |

| Adjustment range | 5-75mm |

| Hydraulic oil volume | 50L |

| Equipment size | 960*950*1600mm |

| Weight | 700kg |

METAL RING MAKING EQUIPMENT

Metal ring forming equipment The product made in this equipment acts as a ring that reinforces the center of the abrasive disc. In this equipment, the finished products are also sent to the automatic abrasive disc preparation equipment.

| Metal mold making equipment (press) | |

| Nominal pressure | 400KN |

| Stroke speed | 45ps/min |

| Length of vertical columns | 340mm |

| The distance between the center of the liner and the equipment | 250mm |

| Desktop thickness | 65mm |

| Electric motor power | 5,5kw% |

| Weight | 3600kg |

VIBRATING SIEVE

Using a vibrating screen, we clean the abrasive grains from large or other objects. We send the cleaned abrasive grains to a two-bowl hydraulic mixer.

| Vibrating sieve | |

| Model | VS -100A |

| Amplitude | 25-30mm |

| Vibration frequency | 4-5sek |

| Chewing efficiency | 15-20kg/min |

| Sieve part | 1 |

| Sieve size | 1080*700mm |

| Size | 1650*650*630mm |

| Power source | 380V 50Hz 3faza |

| Power | 0,55kw |

| Weight | 200 kg |

TWO BASIN HYDRAULIC MIXER

We add the necessary components to the abrasive grains in two-bowl hydraulic mixers and mix them well. The prepared raw materials are sent to the automatic abrasive disc preparation equipment.

| Two bowl hand mixer | |

| Model | MIX-2-100A |

| Useful size | 120L |

| Maximum load weight (abrasive) | 100kg |

| Fork lifting and lowering speed | 42-48 rpm |

| The speed of rotation of the cabin up and down | 10-40min |

| Container size | D900mm*T 400mm, thickness 22mm |

| Installed power | 15 kw |

| Power hungry | 4,5-6kw |

| Power source | 380v 50hz 3faz |

| Each container size | 2200*1200*1580 |

| Weight | 4200 kg |

ABRASIVE DISC PREPARATION EQUIPMENT (100,115,125 mm)

Abrasive disc preparation equipment produces 100, 115, 125 mm abrasive discs in these small sizes. The equipment automatically fills abrasive grains, glass fiber chips, colored aluminum oxide on the surface.

| Cutting lisk preparation equipment | |

| Model | PRS-P46T125A45 |

| Production diameter | 100,115,125mm |

| Thickness | 1-7mm |

| Nominal pressure | 1250kn |

| Structure | 46 workstations |

| Management mode | Plc touch screen display |

| Work rhythm | Grinding time is 6-9 seconds |

| Air cylinder | SMC |

| Power | 25kw |

| Power source | 380v 50hz 3faz |

| Weight | 5500 kg |

ABRASIVE DISC PREPARATION EQUIPMENT (150,180,230 mm)

Abrasive disc making equipment produces 150, 180, 230 mm abrasive discs in these large sizes. The difference between this equipment and the small abrasive disc making equipment is only in the width of the dies. This equipment also automatically fills the surface with abrasive grains, glass fiber chips, and colored aluminum oxide.

| Cutting disc preparation equipment | |

| Model | PRS-P42T250A679 |

| Production diameter | 150,180,230mm |

| Thickness | 1-7mm |

| Nominal pressure | 2500kn |

| Structure | 42 workstations |

| Management mode | Plc touch screen display |

| Work rhythm | Grinding time is 8-12 seconds |

| Air cylinder | SMC |

| Power | 30kw |

| Power source | 380v 50hz 3faz |

| Weight | 8400 kg |

SPECIAL ELECTRIC OVEN

Using a special electric oven, the products made in the abrasive disc preparation equipment are heated at 200C.

| Electric oven | |

| Model | OVN-304 |

| Internal capacity | 3CBM |

| High temperature | 250C |

| Operating temperature | 180C |

| Installed power | 31,8KW |

| Consumption power | 10-12KW |

| Power source | 380V 50GZ 3FAZ |

| Weight | 150KG |

BALANCE CHECKING EQUIPMENT

The product is taken from a special electric oven and checked using the balance checking equipment. We send the tested products to the equipment that checks the maximum rotation speed.

| Balance checking equipment | |

| Model | SBT-410S |

| Test size | 100-250mm |

| The shape of the cutting disc | T41 |

| Accuracy | 0,3 g |

| Electricity supply | 380v 50hz 3faz |

TEST EQUIPMENT

With the help of testing equipment, you can check the maximum rotation speed of ready-made abrasive discs.

| Testing equipment | |

| Model | STM-1636F40 |

| Maximum working speed | 36000rpm |

| Work size | 100-400 mm |

| Hole size | 16/22/ 25,4mm |

| Accessories | Automatic electromagnetic card, printer |

| Power | 5,5kw |

| Electricity supply | 380v 50hz 3faz |

| Weight | 400 kg |

AIR COMPRESSOR

The air compressor system is an auxiliary device for the abrasive disc preparation equipment.

| Air compressor | |

| Model | AC-BK18-10 |

| Maybe the weather | 1CBM |

| Size | 3CBM/min |

| Power | 18kw |

| Power supply | 380v 50 hz 3 faz |

| Weight | 500kg |

Video footage of the line’s operation

Based on 0 reviews

Be the first to review “Abrasive disc production line for metal cutting” Cancel reply

Related products

-

Construction equipment, Solution product lines

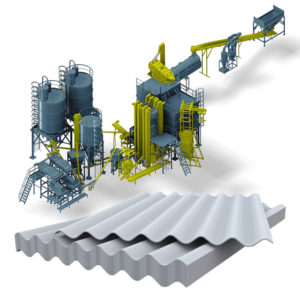

Asbestos slate panel production line

Rated 5.00 out of 5(0)When building a building, its upper part, i.e. the roof, is very important, because it acts as an umbrella that protects the building from external influences. In the markets of our country, you can see the types of roofs made of different materials. The most common among them are slates made of Asbestos cement. Did you notice that these slates have always been around and have not been discontinued. There are reasons for this, and because of these properties, Asbestos Slates are always in use and remain the most sought-after building material. And the company “AFEX Group” presents to you exactly this ASBESTOS SLATE PRODUCTION LINE. Do you know why this product is still popular? Because:

SKU: n/a275,000$ -

Construction equipment, Solution product lines

Composite fittings production line

0 out of 5(0)Composite rebar (also known as fiberglass reinforced plastic or composite rebar, mesh) is steadily replacing traditional steel rebar in construction around the world. FRP rebar is made from a mixture of ultra-strong glass or basalt fibers and bonding resins, resulting in construction-grade rebar with superior performance over steel. Synthetic resins are used as a binding agent for fibers, protect fibers from mechanical effects and harmful effects of the environment during the production and operation of the product.

SKU: n/a38,000$ -

Construction equipment, Metalworking equipment, Solution product lines

Self-tapping screw production line AF-008

Construction equipment, Metalworking equipment, Solution product lines

Construction equipment, Metalworking equipment, Solution product linesSelf-tapping screw production line AF-008

0 out of 5(0)Among the building materials, one of the most widely used products is samorez. Buyers appreciate the wide range of applications and long service life. Many entrepreneurs ask the question whether it is better to produce samorez, or whether ordinary nails are used a lot by our people. Both products have their own conveniences and their own niches. For example, you can’t use nails to make wooden furniture, but it’s difficult to use a screwdriver for asbestos slates. We recommend a complete line for those who want to start the production of the most commonly used vernacular called “black Samorez”. “AFEX-GROUP” LLC company decided to recommend a line perfected as a result of long-term research. Some of the Samorez products produced by our current local manufacturers object to the fact that the head part breaks quickly or rusts after a short period of time. And many people think that it is from the raw material, it depends a lot on the right raw material, but since the product quality of two different manufacturers using the same type of C1022 wire is different, then the error is in the production equipment or depends on the process in it.

SKU: AF-L008129,500$ -

Construction equipment, Metalworking equipment, Solution product lines

Mix production equipment AF-L011

Construction equipment, Metalworking equipment, Solution product lines

Construction equipment, Metalworking equipment, Solution product linesMix production equipment AF-L011

0 out of 5(0)We have decided to provide you with a nail production line based on the demands of many of our customers. Mix is currently considered one of the most popular building materials in construction works in our country. Mix production business is considered more effective than other businesses as it allows you to get quick income and easy to find buyers for your products. You can get to know the production process closely through our recommended line below.

SKU: AF-L011128,000$

There are no reviews yet.