Metal cylinder containers production line

Out of stock

“AFEX-GROUP” offers a production line of metal containers with hooks from 1 liter to 5 liters with high profit for our entrepreneurs. For our customers who purchase this line, our company will provide close practical support in starting this activity.

118,000$

Out of stock

Today, the demand for metal boxes is growing year by year. Because these products are used in many industries, for example; It is used for packing tea, vegetable and fruit products, canned meat and fish, oils, varnish materials, chemicals, gifts and souvenirs, confectionery and other food products.

“AFEX-GROUP” company provides information on the modern semi-automatic technology, which is useful in the packaging of lacquer-paint products from 1 liter to 5 liters, aimed at the production project of metal containers!

Raw materials

Depending on the types of products to be packed, 3004/3104, 5042/5182 brand metal sheet materials can be used.

Necessary infrastructures to start operations

Required area; It should not be less than 150 m².

Electric energy; 77 KW/380 V.

Number of workers; 10-12 people.

Line equipment

1. Equipment for cutting to size.

2. Circle forming equipment.

3. Welding equipment.

4. Circular bending equipment.

5. Connecting equipment.

6. Welding (for hook) equipment.

7 Stamping (press) equipment.

8. Equipment for bending the cover circle.

9. Chiller.

Cutting-to-size equipment – With the help of the equipment, metal sheets with a width of 1 meter, a thickness of 0.35 mm, and a minimum cutting width of 52 mm can be cut to the required sizes. In this equipment, the metal sheets cut to the specified sizes are sent to the circle forming equipment.

| Technical indicator | |

| Plate thickness | <0.35 mm |

| Roll width | < 1050 mm |

| Minimum width | > 52 mm |

| Power | 1.1 kw |

| Size | 1500*1200*800 mm |

| Weight | 1400 kg |

Circular forming equipment – This equipment can produce circular metal boxes with a circular diameter of 65-300 mm and a height of 50-400 mm. Formed circular metal sheets are sent to welding equipment.

| Technical indicator | |

| Diameter | 65-300mm |

| Height | 50-400mm |

| Size | 700*700*840mm |

| Weight | 40 kg |

Welding Equipment- This equipment joins together and welds formed circular metal sheets. The equipment can be used for the production of round metal cans with a diameter of 52-300 mm, a height of up to 400 mm, i.e. from 0.5 ml to 20 liters.

| Technical indicator | |

| Diameter | 52-300mm |

| Height | 400mm |

| Thickness | 0.5 mm |

| Power | 15 kw |

| Size | 1700*1500*2050 mm |

| Weight | 700kg |

Circle Bending Equipment – At this stage, the welded circular boxes are bent at 45° to join the upper and lower lids of the circle. The boxes made in the machine are sent to the next machine to combine the top and bottom lids with the box body.

| Technical indicator | |

| Opportunity | 30 boxes/min |

| Diameter | 52-300mm |

| Height | 400mm |

| Thickness | 0.5 mm |

| Power | 15 kw |

| Size | 1700*1500*2050 mm |

| Weight | 700kg |

Joining equipment – this equipment is used to join the top and bottom covers with the body of the box.

| Technical indicator | |

| Opportunity | 20-30 boxes/min |

| Diagonal | 40-180mm |

| Power | 1,5 kw |

| Size | 800*500*1650 mm |

| Weight | 500 kg |

Welding (Hook) Equipment- If you want to make metal containers with hooks, this equipment is required. In the equipment, the hook is welded to the body of the box (metal details prepared in the stamping equipment). (This metal part is not included in the equipment or mold line, please contact our company for more information.)

| Technical indicator | |

| Opportunity | 20-30 boxes/min |

| Power | 45 kw |

| Size | 1400*900*1400 mm |

| Weight | 600 kg |

Stamping (press) equipment – 5 pieces of this equipment are included in the line, because the production of upper and lower covers includes 5 processes. That is, 5 molds are required. There is 1 stamping die for the upper cover, 1 stamping die for the lower cover, 3 stamping dies for the ring circle.

⚠️ When starting your activity, you can buy the necessary amount of these equipments, based on your ability. You can apply 5 technological processes in the production of top and bottom caps using one or two tool changeover methods. But this technological process leads to a sharp drop in production volume. Therefore, since each mold requires the purchase of equipment, the 5 equipment prices are shown in the line total.

| Technical indicator | |

| Nominal power | 250KN |

| Shaping depth | 80mm |

| Press shot | 60 min |

| Hole sizes | 180*130*260 mm |

| Power | 2.2 kw |

| Size | 1325*990*2140 mm |

| Weight | 1900 kg |

The lid circle bending equipment is used to completely re-bend the 45° bent part of the central lid in order to close the lid and increase the quality level.

| Technical indicator | |

| Opportunity | 25-30 units/min |

| Diameter | 30-160mm |

| Height | 32-300mm |

| Power | 0.37 kw |

| Size | 790*600*1360 mm |

| Weight | 200 kg |

Chiller- For cooling with air. The device is mainly an auxiliary device for welding equipment.

Based on 0 reviews

Be the first to review “Metal cylinder containers production line” Cancel reply

Related products

-

Metalworking equipment, Solution product lines

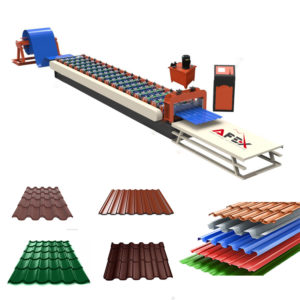

Equipment for the production of metal tiles (profnastil).

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesEquipment for the production of metal tiles (profnastil).

Rated 5.00 out of 5(0)Profnastil products are an integral part of construction. Almost all local constructions have demand for profnastil products, taking this into account, the company “AFEX-GROUP” offers you profnastil production equipment below.

SKU: n/a14,700$ -

Metalworking equipment, Other equipment

Leather belt production line

0 out of 5(0)Most of the leather belts are imported products. That is why we believe that the production of this product in the territory of our country will give you good results. We first need raw leather or a leather substitute to make the product. 10 types of equipment are involved in the production process, and our company recommends these equipments to you at the most reasonable prices.

SKU: n/a25,700$ -

Construction equipment, Metalworking equipment

Gypsum board profile production equipment (double mold)

Construction equipment, Metalworking equipment

Construction equipment, Metalworking equipmentGypsum board profile production equipment (double mold)

0 out of 5(0)Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles began to take the place of wooden slats on the market.

SKU: n/a14,800$ -

Metalworking equipment, Solution product lines

Metal pipe and profile production line

0 out of 5(0)We will continue to provide detailed information on profitable businesses and technologies for customers of AFEX GROUP! Stay tuned!

Shaped pipes and profiles are considered one of the widely used products today in many fields – automotive industry, construction, metallurgy, gas pipelines, greenhouses, tables and chairs, doors, light constructions and other fields. The business of production of shaped pipes has become a very promising business direction today. Of course, the buyers of products are not only large enterprises, iron markets and individuals, but also successful buyers. Of course, not every region has factories or workshops that produce such products, so why not still take advantage of the space and start your own manufacturing enterprise?

SKU: n/a198,700$

There are no reviews yet.