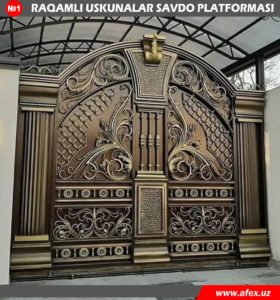

Metal door production line

Out of stock

Doors, including steel doors and gates, are always in demand. Modern polished steel doors and gates represent an ever-necessary home component. Therefore, the production of steel doors in the world market, this type of activity is a promising business idea, although the competition in this field is relatively high. Almost everyone can organize this activity, because the production of doors is not a technologically difficult activity.

323,500$

Out of stock

“AFEX-GROUP” offers modern and high-quality technology for our entrepreneurs who want to start working in this field. With the help of this equipment, you can produce not only metal doors, but also details necessary for the production of other types of products.

Today, the production of steel doors in our country has become a profitable but competitive business. Of course, there are competitors in this field, but the level of demand is still low. Ways to overcome competition in this field are easy to innovate with unusual design, non-standard shapes and sizes. The fact that construction works in our country continue for 4 seasons ensures the constant level of demand.

Major buyers of this activity;

*Private developers.

*Construction companies.

*Owners of apartments in new buildings.

*Residential households.

In recent years, the construction of high-rise buildings in our country continues to grow significantly, if you purchase this equipment from us and enter into a contract for the supply of iron doors with construction companies, you will soon cover the cost of the equipment and make a profit. possible

Necessary infrastructures for starting the activity;

Required area; the ceiling height should be 6 meters (to the press equipment), not less than 200 m².

Electric energy; 110 KW/380 V.

Number of workers; 8-10 people.

Line equipment and devices;

1. Forming Press equipment.

2. Cutting equipment

3. Forming equipment

4. Perforating equipment

5. Mechanical Press Equipment

6. Bending equipment

7. Welding equipment

8. Hot pressing equipment

9. Vacuum print

First, let’s briefly introduce the working mechanism of the forming press equipment and the devices in it.

Forming Press Equipment – High-pressure hydraulic press equipment with 2500 tons of force is capable of forming metal sheets with a thickness of 2.2 mm and a working table size of 1500×2500 mm. The equipment is equipped with modern and high-quality devices.

Hydraulic system

The hydraulic system is located on the right side of the press and consists of oil tank, high pressure pump, motor, valve cartridge and other components.

System cartridge valve

A cartridge valve system is installed in the equipment to prevent liquid leakage. All oil supply pipes to the equipment use a combination gasket, covered with rubber on the inside and copper on the outside by the manufacturer, compared to iron used by other manufacturers, the advantages are as follows:

*The flexibility of red copper is strong, the connection is strong;

*Copper rubber effectively protects leather from breakage during high-pressure washing.

Scheme of hydraulic station

A horizontal oil pump is different from other pumps in the hydraulic station

used, to reduce the heat generated during oil pulling. Oil in the system

rises slowly, and the temperature is around 55 degrees, which means that the equipment is always the same

is a proof of its operation and long service life.

Technical indicator

Features 2500T

Max sheet thickness Metal 2.2mm

Strength Stainless metal 1.6mm Aluminum 1.8mm

Opening height 25000KN

Return force 500mm

The size of the desktop is 630x2KN

The speed of descent is 1500x2500mm

Working speed 120mm/s

Return speed is 5-10mm/s

Return speed 80mm/s

Power 22x2kw

The size is 3400*2800*4800mm

Weight 40T

Equipment forming molds can be purchased by the customer according to their requirement. Molds

prices are determined depending on the types of forms.

The metal sheets formed in the pressing equipment are the doors to the next steps

sent for preparation.

The cutting equipment is designed by ANSYS software, which is cutting

is modern equipment that works with reliability and precision. To cut into equipment

the required size is determined. The back panel will automatically adjust to this size. It is E21 S

can be programmed by system management and store up to 40 programs.

The equipment has 0.05 mm high precision cutting capabilities.

The cutting angle, i.e. the distance between the cutting blades, can be adjusted using a motor.

All processes are performed using CNC software. Legs in case of emergency

with the button, the equipment can be stopped immediately.

| Technical indicator | |

| Maximum cutting thickness | 4mm |

| Maximum cutting length | 3200 mm |

| Cutting angle (adjustable) | 30-1 30 |

| Cutting size | up to 500mm |

| Cutting speed | 14-35 min |

| Cutting edge length | 1100*3 mm |

| Amount of cutting edge | 3(top)+3(bottom) pieces |

| Motor power | 5.5 sq |

| Size | 3840x1600x1620mm |

| Weight | 4500 kg |

Modeling equipment – this equipment is developed by ANSYS software, and

it reliably and accurately creates the desired shapes when bending door frames

is modern equipment that works.

| Technical indicator | |

| Nominal pressure | 1000KN |

| Max bending (bend length) | 3200 mm |

| Max opening height | 370mm |

| Motor power | 7.5kw |

| Size | 3200x1600x2600mm |

| Weight | 5600 kg |

Perforating equipment – this equipment has holes for locks of the required sizes

it is used for making, cutting and bending works. Each cylinder is independent

the operation is ensured, the number of cylinders is individual, the customer’s request, i.e. the door frame and

depending on the door style.

Technical indicator

Nominal pressure 300-500KN

Motor power is 4kw

Voltage 380V

The size is 3865x2140x2350mm

Mechanical Press Equipment- At this stage, the edges of the door frames are pressed before bending

are cut based on pre-entered dimensions using mechanical press equipment.

The equipment works on the mechanism of pressing and cutting.

| Technical indicator | |

| Nominal pressure | 400KN |

| Stroke speed | 45/min |

| Length of vertical columns | 340mm |

| The distance between the center of the slider and the hardware | 250mm |

| Desktop thickness | 65 mm |

| Motor power | 5.5kw |

| Weight | 3600 kg |

Bending equipment – this equipment is used to bend the lower and upper parts of doors

is used.

| Technical indicator | |

| Sheet thickness | 0.3-1.5mm |

| Bending angle | 60 |

| Processing length | 2500 mm |

| Size | 3680x800x1590mm |

Welding equipment – carrying out contact welding works with the help of electric current

is an effective tool to get going. The line includes 1 piece of welding equipment

caught. Customer can purchase add-on as per their requirement.

| Technical indicator | |

| Tension | 380V |

| Current setting | 25-270A |

| Current voltage setting | 15-27.5V |

| Protection level | IP21 |

| Size | 580x290x550mm |

| Weight | 28.5 kg |

Hot pressing equipment – Equipment for doors with special oil at a temperature of up to 85 C

used to dry the applied glue and level the balance of the doors. Equipment

can be opened and closed automatically at the specified time.

| Technical indicator | |

| Number of layers | 10 |

| Number of cylinders | 4 |

| Pressing power | 100kn |

| Distance between layers | 110mm |

| Pressing temperature | 85c |

| Paste time | 15-30 min |

| Size | 2860*1260*2910 mm |

| Weight | 12500 kg |

Vacuum print- Equipment based on a vacuum mechanism. Prepared for this equipment

The doors are brought in a painted state, then the surface part with the desired flower paper

combined and inserted into the equipment. Equipment at a temperature of up to 240C for a certain time

After heating and vacuum absorption, the flower paper structure appears on the surface of the door

will be

| Technical indicator | |

| Operating temperature | 240 C |

| Desktop size | 2400*1400 mm |

| Efficient printing area | 2200*1200mm |

| Starting power | 24kw |

| Working power | 10kw |

| Motor power | 0,75kw |

| Efficiency | 5min |

| Print depth | 15min |

| Size | 2900*1600*1700mm |

| Weight | 800kg |

| Prices | |

| Forming press equipment | |

| Cutting equipment | |

| Forming equipment | |

| Drilling equipment | |

| Mechanical press equipment | $ 268 000 |

| Bending equipment | |

| Welding equipment | |

| Hot pressing equipment | |

| Vacuum printing equipment | |

| Travel expenses for 3 containers |

Based on 0 reviews

Be the first to review “Metal door production line” Cancel reply

Related products

-

Construction equipment, Metalworking equipment

Gypsum board profile production equipment (double mold)

Construction equipment, Metalworking equipment

Construction equipment, Metalworking equipmentGypsum board profile production equipment (double mold)

0 out of 5(0)Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles began to take the place of wooden slats on the market.

SKU: n/a14,800$ -

Metalworking equipment, Solution product lines

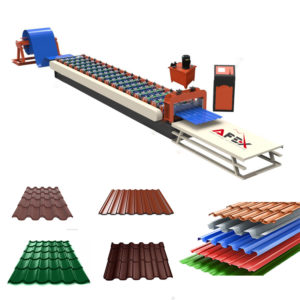

Equipment for the production of metal tiles (profnastil).

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesEquipment for the production of metal tiles (profnastil).

Rated 5.00 out of 5(0)Profnastil products are an integral part of construction. Almost all local constructions have demand for profnastil products, taking this into account, the company “AFEX-GROUP” offers you profnastil production equipment below.

SKU: n/a14,700$ -

Metalworking equipment, Solution product lines

Fully automatic aluminum foil container packaging equipment

Metalworking equipment, Solution product lines

Metalworking equipment, Solution product linesFully automatic aluminum foil container packaging equipment

0 out of 5(0)The equipment is 20-999mm long, and can realize the features of automatic lubrication, automatic self-maintenance and automatic self-control of all parts of the set with a fully automatic operation system.

SKU: n/a49,000$

There are no reviews yet.