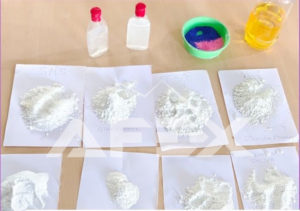

Washing powder production line

Modern washing powders are presented in a very wide range and can have different release forms:

powder;

gel or liquid concentrate;

granules;

soluble tablets.

Today, before considering the necessary equipment for organizing the production of washing powder, we would like to dwell a little on the types of washing powder and the situations in which they can be used.

9,900$

There are the following types of laundry detergents:

- Anionic substance represents the biggest danger for human health, especially for children, it causes allergic reactions, lowers immunity, damages internal organs and nervous system.

- Cationic. The substance does not have detergent properties, they are used as a special additive. Nonionic. Relatively safe, biodegradable. Some of them are made from natural ingredients.

- – Phosphates (sulfates). These are compounds of phosphoric acid salts. Softens water by activating the surfactant and preventing the formation of scale on the parts of the washing machine. It is harmful to human health and pollutes nature.

- Enzymes fight difficult stains: stains from blood, coffee, oil, etc. Not suitable for washing things made of wool or silk. Their abundance in the composition negatively affects the properties of the fabric.

- Bleach: Chlorine. They whiten the fabric, but can damage it. it is also harmful to humans.

- Oxygen is designed for washing clothes at high temperature, suitable for people prone to skin irritation and allergic reactions.

- Antiresorbents. Prevents dirt particles from returning to the fabric during washing.

- Flavoring substances neutralize the smell of chemicals, but in some cases the probability of causing an allergy is high.

As a manufacturer, you should determine which type of washing powder to produce based on your consumer segment.

Features of the line

Mixer

Drying equipment

Product delivery equipment

Washing powder packaging equipment

Tape packaging equipment

Necessary infrastructures to start the activity:

- Required area: should not be less than 25-35 m².

- Electric power: 6-8KW/ 220/380 V.

- Number of workers: 2-3 people.

Mixer

First, the raw materials are mixed in the required proportion into a mixer device, and a homogeneously mixed product with relative humidity is formed. In order to avoid dusting of the products during the mixing process, it is recommended to mix them at low speed and use a mixer with a lid. As the mixed mass is slightly wet, it is recommended to dry it quickly.

| Manufacturer | China |

| Motor power | 4 Kv |

| Mixer capacity | 150L |

| Rotation speed | 90r/minute |

| Voltage | 380 V |

| Size | 1222*830*835mm |

| Theft | 180 kg |

Drying equipment

For drying, the product is sucked from the mixer with the help of special vacuum extraction equipment. The absorbed product is dried using special equipment. You can change the build temperature, time and speed as you wish. The parts of the equipment that come into contact with the product are made of stainless metal as much as possible.

| Manufacturer | China |

| power | 1,1 Kv |

| Capacity | 100L |

| Drying time | 10-15/minute |

| Size | 840*540*1620mm |

Product delivery equipment

It is recommended to collect raw materials for packaging after they are dry. The sieving process allows you to separate the parts that have stuck together due to moisture and ensure that your product is of high quality when packaged. Depending on the type of product you are making, you will be able to change the size of the sieve.

| Manufacturer | China |

| power | 750 Kv |

| Voltage | 220v 380v |

| Sieve diameter | 500 mm |

| Sieve height | 80 mm |

| Package size | 660*660*960mm |

| Weight | 80kg |

Laundry Day Packaging Equipment

Great care is required when choosing packaging equipment for this product. This is because measuring packaging equipment is not very suitable for washing powder due to its size. The reason is that the density of washing powder is not always the same depending on the ingredients in it, so we recommend our customers to use packaging equipment specially used for products with scales and dust. This equipment is also suitable for packing other powder products. With the help of a special screw conveyor, the product is delivered to the packing hopper. The product in the packing hopper is filled into special packaging bags with the help of one worker, and with the help of special equipment designed to close its mouth, the packaging is completely closed, and it is ready for sale.

| Manufacturer | China |

| power | 750 Kv |

| Voltage | 220v 380v |

| Material | 304 stainless steel |

| Measurement quantity | 100-2000 gr |

| Weight | 120 kg |

| Control Panel | PLC control with touch |

| Measurement method | Microcomputer scale method |

Tape packaging equipment

With this equipment, you stick the bags filled with flour on the upper part through the iron rollers at a special temperature, and your product looks ready for sale. Because it is somewhat difficult to hold a heavy product by hand during the packaging process, there is a special moving tape under the equipment.

| Manufacturer | China |

| power | 1,2 Kv |

| Voltage | 220v 50hz |

| Efficiency | 0-15 m/min |

| Packet length | 250mm |

| Pack width | 600 mm |

| Package thickness | 0,02-0,02 mm |

| Lifting weight | 5kg |

| Heat temperature | 0-300C |

| Equipment size | 85*40*37 cm |

There are no reviews yet.