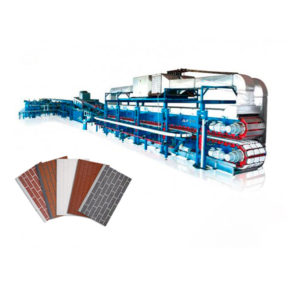

Greenhouse film production line

Out of stock

The demand for quality food products in Uzbekistan and around the world is increasing more and more. For this reason, the use of efficient land use technologies is becoming increasingly important.

499,500$

Out of stock

Members of the AFEX-GROUP company present to our valued customers the greenhouse film production line, which is one of the next big projects. With the help of a common line, you will have the ability to produce high-quality films quickly.

General information

Raw materials: LDPE, LLDPE, EVA and other mixed materials

Max film width: 12000 mm

Number of floors: 3 floors

Film thickness: 0.08-0.12 mm

Production capacity: 800 kg/hour

Voltage: 380V ±5%-10%

Total power: 900 kW

Total dimensions of the line: 18*11*22 meters (length*width*height)

Water temperature: 5-10°C

Water volume: 150 L/min

Equipment list

The production line consists of the following 7 main parts:

- SJ-135/30 extruder system

- SJ-120/30 extruder system

- Filtration system

- Three-stage mold system

- Cooling system

- Packaging system

- Electronic control system

- Production process

So, we can get acquainted with the tasks and technical indicators of the equipment needed in the production process.

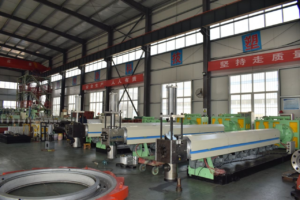

Extruder system

SJ-135/30 extruder

The most important equipment in the line is, of course, the extruder equipment. The function of this equipment is to melt raw materials and release them in packages. The processes are carried out in two stages, that is, a two-stage extruder system. The extruder, in turn, consists of screws, barrels and a reduction box. These main parts ensure the stability and continuity of the process.

Screws

| Screws | |

| Diameter | F 135mm |

| L/D ratio | 30:1 |

| Material | 38 CrMoALA |

| Nitriding thickness | 0,5-0,75mm |

Barrels

| Screws | |

| Screws | F 135mm |

| L/D ratio | 30:1 |

| Material | 38 CrMoALA |

| Nitriding thickness | 0,5-0,75mm |

Reducer

The function of the reduction box is to control the amount of raw materials entering the extruders and to provide the necessary pressure to the necessary extruder equipment.

| Reduction box | |

| Material | Alloy steel 20CrMnTi |

| Type of cooling | By turning water |

| Motor power | 185KW |

SJ-120/30 Extruder

Further processes continue in the second stage extruder.

| Screws | |

| Diameter | F 120mm |

| L/D ratio | 30:1 |

| Material | 38CrMoALA |

| Type of nitriding | HV 700-940 |

| Nitriding thickness | 0,5-0,75mm |

Barrels

| Barrels | |

| Diameter | F120mm |

| L/D ratio | 30:1 |

| Material | 38:CrMoALA |

| Type of nitriding | HV 700-940 |

| Nitriding thickness | 0.5-0.75mm |

Reducer

| Reduction box | |

| Material | Alloy steel 20CrMnTi |

| Type of cooling | By turning water |

| Motor power | 160kw |

Filter system

In order to increase the quality of the material and the durability of the product, it is necessary to pass the melted raw materials through a filter. This will help save time and energy later in the production process. A cylinder or hydraulic filter can be used in the equipment. Finding these types of filters is not a problem.

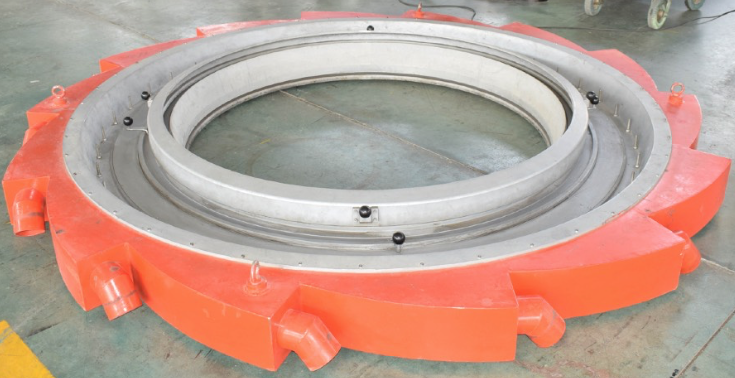

Three-layer molds

Molds are mainly needed to change the parameters of the film. The thickness and dimensions of the film can be changed with the help of molds. The three-stage operation of the molds ensures the high quality of the product.

| Three-layer molds | |

| Type of molds | Triple helix |

| Interval of molds | 2 mm |

| Diameter | 1500 mm |

| Metal | 42CrMo tempered steel |

| Temperature control | Through the control point |

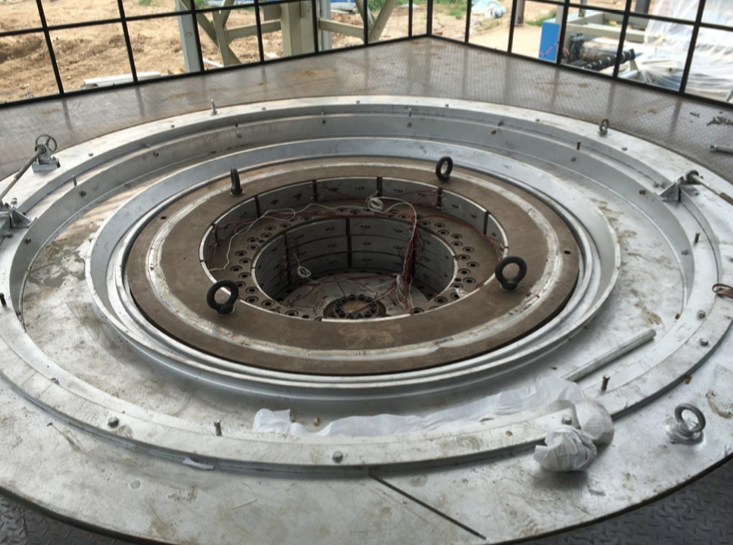

Cooling system

This line consists of two types of cooling systems: internal and external. The external cooling system consists of a disk ring.

The internal cooling system is systematically connected with all the equipment in the line. All ventilation equipment in the equipment uses a total of 30 KW of electricity. We can see it in the following videos.

Measuring system

At the next stage, we will have to measure the finished products to the desired length and cut it. This task is performed by cutting rollers.

| Measuring roller | |

| Roller size | F 260*3500mm |

| Metal | NBR rubber |

| Motor power | 5.5kw |

| Max speed | 35m/min |

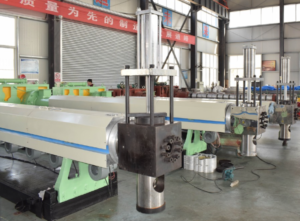

Packaging system

At the last stage of the production process, we wrap the finished products. This wrapping is done using special equipment.

| Wrapping equipment | |

| Type of wrapping | 2 center winding |

| Speed | Max 25m/min |

| Max roll diametric | F 300mm |

| Metal | 38CrMoALA |

Video footage of the process

Prices

SJ-135/30 extruder system

Sj-120/30 extruder system

Filtration system

Three-stage mold system $ 370 000

Cooling system

Wrapping system

Electronic control system

Logistics costs (7 containers) $18500*7=$129500

There are no reviews yet.