Gypsum board profile production line AF-L030

Out of stock

Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles are rapidly replacing wooden slats in the market. But in our opinion, there are some disadvantages in the production process of plasterboard profile available on the market:

18,700$

Out of stock

- Due to the smooth surface of the plasterboard profile, it is somewhat difficult to harden a self-tapping screw into it, and sometimes it leads to a hole in a place other than the one you intended;

- The plasterboard profile has a standard length, and customers do not have a choice for a product of other lengths. This causes some difficulties in large-scale construction works;

- Since plasterboard profiles do not have special measuring lines, it is always necessary to use a meter when working with them, and this leads to excessive time and labor consumption during construction;

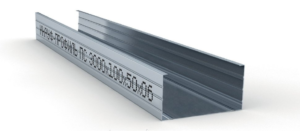

- You once used high-quality plasterboard profiles, and the next time you can find it, because the manufacturers do not print their brands on the profiles, and this leads to the fact that their customers do not recognize them;

- Each profile should have information about its size and metal thickness, and this is available in other foreign countries, but not in our country;

When you first introduce a new product to the market, you need to quickly establish a niche for your product in the market. For this, do a deep analysis of the products of your competitors in the market and add to it the conveniences that your competitors do not have or that can be given to people through that product, and we believe that you will quickly find your customers. Believe me, there are always those who choose quality and branded products.

Let us now offer you a new type of equipment for modern plasterboard profiles, eliminating the above shortcomings.

AFEX-GROUP doesn’t just sell you equipment, we sell you modern ideas. Therefore, the business you start with us will definitely pay off. Our line has unique conveniences:

- The equipment works on a modern touch screen PLC control system;

- The equipment is equipped with an INVERTER for high-precision operation;

- Hardware can store commands in memory; (for example, if you order the equipment to produce 200 profiles of 5 meters, it will execute the command you gave);

- The equipment can produce a profile of unlimited length;

- An additional auxiliary laser marking device is added to the equipment, which is used to lower longitudinal lines to measure the surface of the profile, leaving a special line every 10 cm. Also, this equipment includes its technical parameters on the surface of the product.

- The equipment can work with painted and galvanized metal sheets.

- In order to make it easy to transfer shurp to the profile, it leaves a special small hole-shaped concave mark on the surface, and these points also increase the strength of the profile.

EQUIPMENT FOR HORIZONTAL CUTTING OF SHEETS INTO PIECES

| Equipment for horizontal cutting of sheets into pieces | |

| Manufacturer | China |

| City | Botou |

| Tin thickness | 0.3-0.8mm |

| Roller material | 45# chrome metal |

| Speed of operation | 8-12m/min |

| Base thickness | 16mm |

| The width of the incoming tin | 600-1250mm |

| Voltage | 380v50Hz |

| Weight | 600 kg |

| Power consumption | 3kw/h |

PROFILE MANUFACTURING EQUIPMENT

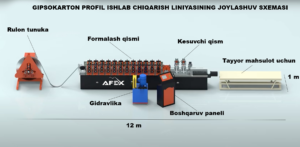

The profile production equipment is manufactured by an advanced Chinese company, and the rollers are made of CR12 hardened metal so that the rollers do not wear out quickly. The new exterior design and separate control panel provide you with many conveniences in use. The equipment includes the following parts:

- Lifting device for rolled tin

- Part of profiling

- Hydraulic pump part

- PLC control panel

- A special table for finished products

- Spare parts

| Manufacturer | |

| City | China |

| Tin thickness | Botou |

| Roller material | 0.3-0.8mm |

| Speed of operation | 45# chrome metal |

| Base thickness | 8-12m/min |

| Equipment size | 16mm |

| Voltage | 5000*1000*1500mm |

| Weight | 380v50Hz |

| Management system | 2 tons |

LASER MARKING EQUIPMENT

Laser marking equipment is used to imprint the required information on this profile. This information also includes the measurement of the profile.

| Manufacturer | |

| City | China |

| Cooling method | Guangzhou |

| Work program | By air |

| Laser power | EZCAD |

| Accuracy level | 20W |

| Marking speed | 0.02mm |

| Voltage | 0-7000mm/s |

| Power consumption | 220v50hz |

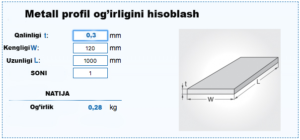

Using the above example, you can see the result of calculating the weight of a 1 meter long 0.3 mm thick metal profile. Now let’s find out the price from the wholesale tin and calculate how much our 1 meter profile will cost. Of course, this is important for you. Later, based on this account book, you can offer a price for the market. Of course, don’t forget to include taxes, electricity, and labor.

| Calculation | |

| The price of 1000 kg tin sheet is | 900$ |

| The price of 1 kg of tin foil is | 0,9$ |

| The price of 0.28 kg is | 0,25$ |

| So the cost of one meter of profile | 0,25$ |

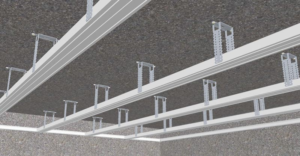

Here are some examples of areas where metal profiles are used:

| Prices | |

| The equipment for horizontal cutting of sheets into pieces is | 2900$ |

| Profile production equipment | 11900$ |

| Laser marking equipment | 3900$ |

| Total | 18700$ |

Based on 0 reviews

Show reviews in all languages (1)

Be the first to review “Gypsum board profile production line AF-L030” Cancel reply

Related products

-

Construction equipment, Metalworking equipment

Gypsum board profile production equipment (double mold)

Construction equipment, Metalworking equipment

Construction equipment, Metalworking equipmentGypsum board profile production equipment (double mold)

0 out of 5(0)Gypsum plasterboard products have entered the modern construction industry at a rapid pace, and in turn, the demand for accessories necessary for the installation of this product has increased significantly. Due to the increase in demand, metal profiles began to take the place of wooden slats on the market.

SKU: n/a14,800$ -

Metalworking equipment

AF-N7 Metal pipe winding tracer

0 out of 5(0)The advantages of the metal pipe wrapping machine are: simple operation, high production efficiency, stable forming effect, high speed and other features.

Pipe materials: stainless steel/copper/carbon steel/iron/galvanized/aluminum etc.

Application: Pipes designed for furniture, construction and other industries.

SKU: n/a11,900$

There are no reviews yet.