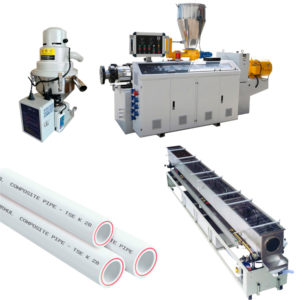

EPS decorative products production equipment

Out of stock

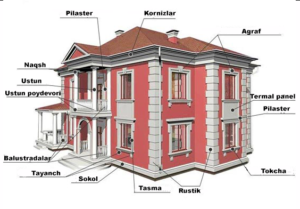

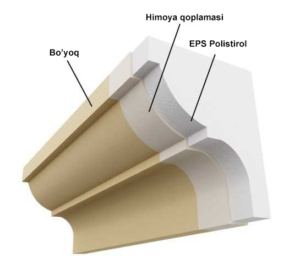

Architecture has been a part of culture for centuries. The first impression of any building is created by its appearance. Architectural relief decoration, which has a very long history, has been used in the formation of the facade for centuries since the time of ancient civilizations. For centuries, architects used solid materials such as stone, marble, and plaster to decorate only palaces, castles, and museums, but now even private homes have become more affordable thanks to new materials such as expanded polystyrene (EPS).

6,000$

Out of stock

“AFEX-GROUP”- offers a project and equipment for the production of decorative 3D panels from EPS products for our compatriots who want to start entrepreneurship with small business activities. This field is one of the developing fields in our country.

Production of EPS decorative 3D panels is a business activity focused on the project of production of panels for interior and facade parts of buildings, based on national and European classical designs.

The demand for these products in our country is growing significantly. You can see the following factors as the reason for this.

Advantages of 3D decoration:

*Cheapness

*Long-term durability

*Quick and easy production

*Easy installation

* Easy implementation of customer requirements

3D decorations can be covered using quartz sand, cement and tile adhesive or white cement, tile adhesive and marble sand. It is advisable to use rodbond or plate glue for gluing.

Required raw materials:

Expanded polystyrene (EPS)

Quartz sand

Cement

These raw materials are cheap and there is no problem in running your business as they are local raw materials.

Necessary infrastructures to start the activity:

Required area; It should not be less than 25 m².

Electric energy; 1.5 KW/220 V.

Number of workers; 1-2 people.

A computer device is also required for this activity.

The equipment produces products using CNC (computer numerical control) control. Learning to operate the equipment is not difficult. The main thing is to learn to cut the desired shapes with perfect accuracy. But you need professionalism. The reason is that you need to have design skills to have many customers and to compete. In this equipment, you can create a product model using a special program on a computer based on the customer’s wishes. All received parameters are then loaded into the equipment program, resulting in the equipment producing the product as specified in the program. Cutting is done using special cutting thread management software. In the production of products, you will need to learn to work with a graphic editor such as CorelDRAW to view three-dimensional images on a computer, that is, to create drawings.

The equipment is equipped with wheels. This, in turn, allows you to move it wherever you want during use.

Although the project is focused on the production of EPS decorative 3D panels, other types of products can also be produced using this equipment.

| Model | Work table | Power | Size | Weight | Price |

| NF1415 | 1450*1370*1280mm | 1000 V | 2000*1500*750mm | 200 kg | $6000 |

| NF1422 | 2150*1370*1280mm | 1000 V | 2700*1500*750mm | 250kg | $6600 |

| NF1430 | 3050*1370*1280mm | 1000 V | 3700*1500*750mm | 320 kg | $9100 |

| NF2030 | 3050*2100*1600mm | 1000 V | 3700*2250*750mm | 350kg | $11 100 |

| NF3030 | 3050*3000*1600mm | 1000 V | 3820*1180*1000mm | 370kg | $12 000 |

| NF4040 | 4050*4000*1600mm | 1000 V | 4820*1180*1000mm | 400kg | $12 600 |

| NF5050 | 5050*5000*1600mm | 1000 V | 5820*1180*1000mm | 450kg | $13 000 |

There are no reviews yet.