Equipment for the production of feminine sanitary napkins

Out of stock

The production of sanitary napkins for women is a highly profitable and promising activity. However, at present, most sanitary napkins are imported to our country from abroad. In our country, the production of products made of non-woven fabrics, for example: baby diapers, wet wipes, medical products, is developing. The production of feminine sanitary napkins is not a technologically complex process, it is almost a process similar to the technology of the production of sanitary napkins.

“AFEX-GROUP” – offers technologically uncomplicated, modern equipment and a profitable project for the production of these products. Of course, our company will provide you with practical assistance in starting your business.

39,700$

Out of stock

Non-woven fabrics are mainly used in the production of feminine sanitary napkins. Of course, today you can find different products in terms of appearance and composition. In addition, like many hygiene products and tools, sanitary napkins have antibacterial properties and are required to prevent the growth of pathogenic microflora. Many entrepreneurs think about the inspections of sanitary centers in the production of these and similar products. However, there are no restrictions on the production technology of this product by sanitary centers.

Various types of non-woven materials were used by the companies for the production of these products.

- Surface (surface part) – made of non-woven material (polypropylene, polyethylene, polyester, viscose);

- Spreading layer – cellulose material made of synthetic or paper;

- The absorbent layer is a combination of cellulose and superabsorbents.

- Adhesive layer- (polymers, synthetic resin);

- Substrate (bottom part) – polyethylene film or fiber material is usually used.

Required raw materials:

PP- special polymer film

PP-Perforated top layer film.

SS- Spunbond non-woven fabric.

Cellulose non-woven fabric.

Cellulose (SAP) is a papery non-woven fabric.

Special glue-synthetic resin.

Necessary infrastructures to start the activity:

Required area; 8 x 4 meters, not less than 35 m².

Electric energy; 12 KW/380 V.

Number of workers; 2-3 people.

Equipment needed for this activity:

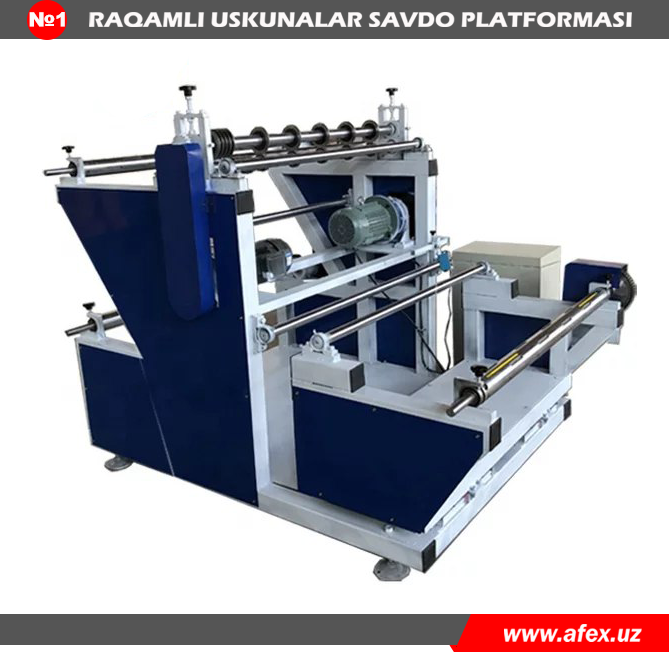

1. Dimension cutting equipment.

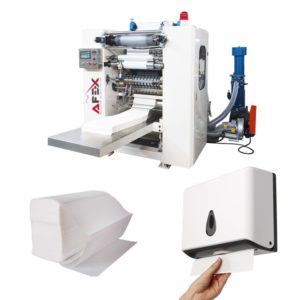

2. Ultrasonic shaping equipment.

Cutting-to-size equipment – The main function of this equipment is to cut fabric rolls with a width of 1600 mm, to cut fabrics to the required sizes for product production. The equipment has 10 cutting blades for the required dimensions, and it is possible to accurately cut paper, film, non-woven fabrics with a width of 20-160 mm.

| Technical indicator | |

| Maximum roll | 1600mm |

| Cutting width | 20-1600mm |

| Cutting thickness | 1-20mmc |

| Cutting speed | 20-100m/min |

| Power | 4,5 kvt |

| Size | 2000*1900*1300mm |

| Weight | 1000kg |

Ultrasonic forming equipment – Ultrasonic, using a special steel roller, without thread and without heating, is a sewing or forming machine. The number of rolls in the equipment is 6, and the tension of each roll can be adjusted separately. During forming, there are options for removing unnecessary waste with a vacuum cleaner and automatic counting.

| Technical indicator | |

| Production capacity | 50-80 pieces/min |

| Napkin Size(LxW) | 260x155mm |

| Tension | 220/380V |

| Power | 7 kW |

| Size | 400*1000*1500mm |

| Weight | 800 kg |

There are no reviews yet.